The construction industry is infamously known to be one of the most dangerous. However, you can beat the odds by staying informed, training your employees, and learning about these must-have tips to stay ahead of the curve.

Whether you’re a construction site manager or business owner, you already know that the industry you and your employees work in can be full of dangers at every turn.

But you can’t ignore the alarming numbers. For a start, fatal construction accidents are double compared to the average in other industries. And about 2.2 million construction working days are lost every year because of this.

Once you pinpoint the main construction site hazards that could put your employees at risk, you’ll be well on your way to finding ways to protect them. But there’s one more thing that can help put these preventative safety measures into practice – an all-in-one software solution.

Prevent All Construction Workplace Hazards With Connecteam

Let’s take a look at some of the most common construction workplace hazards and which of Connecteam’s specific features you can use to prevent them from happening.

7 Construction Site Hazards & Their Solutions

Slips, Trips and Falls

In practically all industries, and especially construction – the most common kinds of accidents are slips, trips and falls. In fact, several thousand workers are injured each year because of trips and slips at construction sites.

Uneven surfaces, unstable grounds, and building sites at varying levels of completion are some of the main construction site hazards that cause these kinds of accidents.

While carelessness, lack of productivity, and distractions also play a huge factor in slips and trips, remaining vigilant and aware of one’s surroundings are key when working on a construction site.

How to minimize these construction hazards:

- Compile safety information in a way that employees can continously reference

- Have inspection checklists ready-made for employees on the clock

- Communicate which surfaces are unstable at the moment

Working At Height

In 2019, a staggering one in five fatal work-related accidents occured in construction. And about a quarter of those incidents came from construction site hazards attributed to working at height. Some of the root causes behind these alarming numbers include:

- Unstable surfaces

- Restricted mobility in high places

- High chances of human error (dropping tools, for example)

- Misuse of safety equipment

How to minimize these construction hazards:

- Ensure that all relevant safety equipment such as ladders, fall protection systems, guardrails are up to standard.

- Train workers on safety tips and your company policy

- Open a safety-specific employee team chat as a backup for last minute updates

Moving & Falling Objects

Falling and moving objects are notoriously overlooked for how common they are. In fact, 96% of nonfatal struck-by injuries in construction are caused by falling/moving objects. Construction sites are rife with objects that are constantly moving and could potentially fall at (forgive us) the drop of a hat.

Significant construction site hazards come from cranes, forklifts, supply vehicles (especially when driving in the winter), heavy equipment, and hazardous materials that are being transported. Also, these objects are often moving in harsh conditions and uneven surfaces. Not to mention the fact that collapse could occur at any given time.

How to minimize these construction hazards:

- Conduct safety meetings to keep workers on the lookout

- Send workers reminder videos or new relevant material of how to protect oneself

- Have employees fill in checklists, to confirm that they are wearing Personal Protective Equipment (PPE)

- Provide “exit and inspection” forms and risk assessments of buildings at risk of collapse.

Protect your business and prepare your team with #1 Construction Safety Management App.

Manual Handling

Construction workers are at a 64% rate of exposure to manual handling, one of the highest rates by industry. While many of these workers are physically capable and qualified to lift heavy objects, the chances of manual handling-induced injuries is still high.

This hazard puts workers at a high risk of the following health issues:

- Musculoskeletal disorder

- Repetitive motion injuries

- Hand-arm vibration syndrome

- Back injuries

Construction teams need to be properly taught how to lift heavy objects. A lack of regular training on the matter can lead to complacency, disengagement, laziness, and bad habits, which can result in the aforementioned injuries (both short and long-term) and even worker fatalities.

How to minimize these construction hazards:

- Conduct full risk assessments

- Provide a list of lifting equipment that each employee should have on hand

- Introduce protocols and workflows that will reduce the time spent lifting/carrying heavy objects.

- Provide safety training resources so that employees can stay clued up on what constitutes safe manual handling.

Excessive Noise

Noise pollution is part and parcel of working on a construction site. But as construction site hazards go, many in the field underestimate its potential to cause serious damage.

For a start – using loud machinery such as drills and compressors for long periods of time can cause long-term hearing problems and can even lead to deafness. Not to mention how distracting noise can be, leading to other accidents in the process.

How to minimize these construction hazards:

- Managers can fill in noise risk assessment forms before workers start each work day

- Perform maintenance checks of PPE and fill in quality control forms

- Provide two-way communication for employees to inform their superiors of noise that they weren’t adequately prepared for

Electrical Hazards

While electricity can be dangerous in all industries, it is one of the most common construction workplace hazards. The harsh, outdoor conditions that construction workers often work in can lead to electrical shocks.

According to OSHA, the following construction site hazards are the most common causes of electrical injuries:

- Direct contact with power lines

- Ungrounded power supply to electrical equipment

- Equipment used inadequately

- Misused flexible cords and extensions

- Lack of ground protection

How to minimize these construction hazards:

- Set-up workplace safety guidelines specfic to electrical work hazards

- Hold an annual safety meeting where employees can ask questions

- Supply training guides on how to detect damaged/exposed wires and understand the severity of coming into contact with electrical current.

- Get employee signatures on their acknowledgment

- Perform safety procedures

- Take photos to confirm that safety warnings and barrier systems are in place.

Harmful Airborne Materials

When it comes to construction, using materials that are potentially very dangerous comes with the territory. If workers on site use damaged PPE or fail to use it properly, then they can expose themselves to harmful materials such as asbestos, as well as dust particles from brick, cement, plaster, and stone.

Construction workers are also at risk from frequent handling of toxic substances such as paint, solvents, adhesives and a variety of other chemicals. This can lead to various eyesight and mouth issues, as well as respiratory conditions such as asthma, asbestosis, silicosis.

How to minimize these construction hazards:

- Employees can complete checklists to inspect the quality of their PPE.

- Minimize exposure of these materials by sharing harmful material handling guidelines and emergency protocols in the event of spillage or accidents.

- Managers can complete risk assessment forms specifically for the storage and handling of the aforementioned materials.

Connecteam: The Ultimate Tool To Prevent Construction Site Hazards

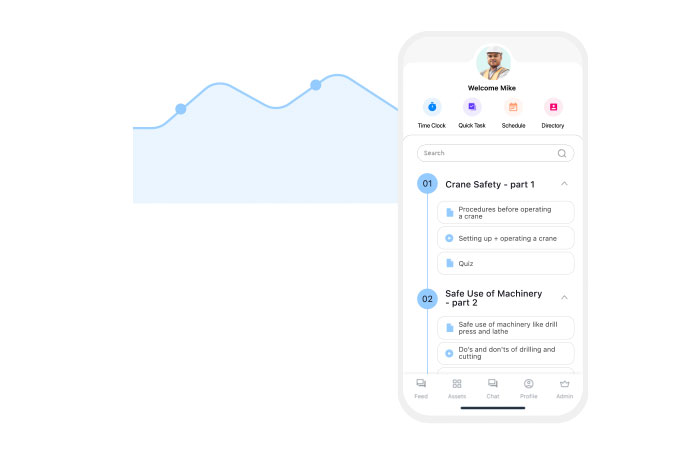

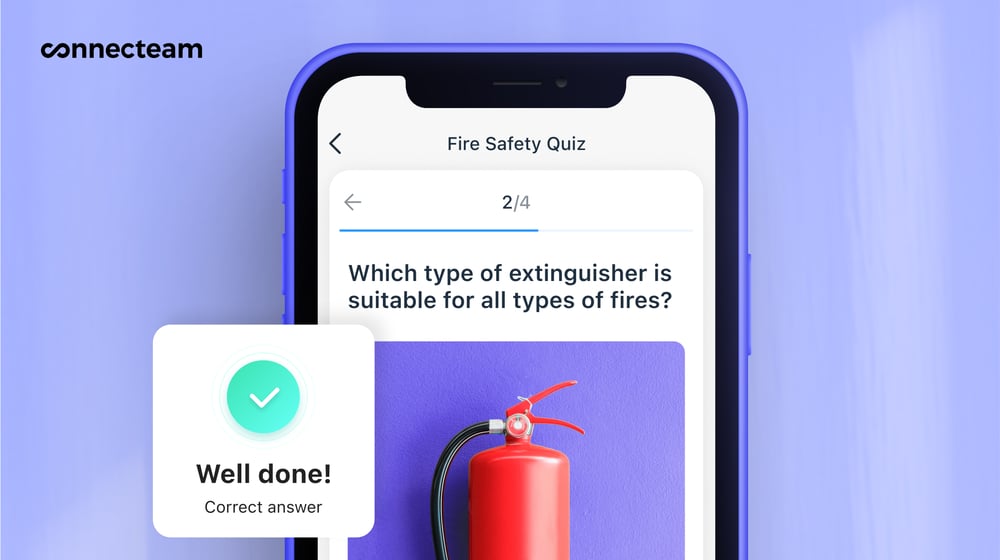

Connecteam is an award-winning app designed for construction and other deskless industries.

More than 36,000 companies (many include construction companies) use Connecteam’s all-in-one app. It is a platform that makes it easy to train employees, maintain instant communication, track work hours, and schedule shifts.

With the forms and checklists, you can finally keep employees accountable and compliant, no matter where they are.

Maximize construction worker safety through documentation:

- Start of Shift Checklists

- End of Job Reports

- Injury/Accident Reports

- Risk Assessment Forms

- Daily Driver’s Vehicle Inspection Reports

- Vehicle Accident Reports

- Scaffolding Inspection Checklists

- Construction PPE Order Requests

- Job Site Inspection Reports

- Equipment Inspection Checklists

As construction workers move around, you can still stay on the same page as them using Connecteam’s employee communication app. Internal communication features include:

- Send images, documents, and in-chat shortcuts to all essential forms

- Announce important safety updates company-wide through the main feed

- Ensure all employees have seen/read your messages with push notifications

- Reach anyone for safety-related matters through the employee directory

Routinely train your construction workers on skills and safety using Connecteam’s employee training. Build comprehensive knowledge bases including all important training resources such as:

- Health and safety guidelines

- Manuals on how to handle heavy objects and harmful materials

- Equipment guides

And so much more.

Use Connecteam’s employee scheduling to ensure your construction workers know exactly when and where they are working:

- Build customizable and easy-to-read shifts

- Include crucial job safety information for better practices

- Book necessary equipment and vehicles for a specific job site

- Receive relevant job details, start-of-shift checklists, safety hazard forms, or end-of-shift reports (as mentioned above).

Easily keep track of employee whereabouts, with Connecteam’s time clock app. Ensure that workers use the clock in and out system at the right location using the app’s geofence and breadcrumbs capabilities. This is extremely beneficial, both from a safety and payroll perspective.

This only scratches the surface of how Connecteam’s construction management app can benefit your business.

The Bottom Line On Construction Site Hazards

All of these construction site hazards (fatal injury and non-fatal) can be reduced significantly with the tips mentioned above.

And of course, pre-construction meetings are a great opportunity to address all potential construction workplace hazards before your workers even step foot on site.

But that’s not all that can make the difference.

Building a quality team ethic and empowering each construction worker to adopt a strong sense of individual responsibility will ensure that harmful incidents caused by construction site hazards are few and far between.

If you combine all of this with an all-in-one construction business app like Connecteam, you can easily start to implement these safety procedures into your daily operations.

Say goodbye to the days of time-wasting back and forth between employees and managers and say hello to efficient construction project management.

Moreover, you will no longer need to spend countless hours writing out workplace safety protocols, risk assessment forms, and checklists using pen and paper. And no more worrying that workers forgot to read and sign them.

So bring these healthy habits into your construction site and implement them with Connecteam’s construction management app to keep your workers safe, engaged and on task all at once.

Keep Your Construction Workers Safe With Connecteam

Everything you need in one place to prevent all construction site hazards