You don’t need to hear from me that construction work is dangerous – you already know it. What you might not know, is that the number of fatalities in the construction industry is the highest compared to all other industries (if you exclude motorway accidents prevalent across all fields of industry).

In fact, the US Bureau of Labor also found that “Fatalities in the private construction industry increased 5 percent to 1,061–the largest total since 2007,” and moreover, they stated that, “Out of 4,674 worker fatalities in private industry in the calendar year 2017, 971 or 20.7% were in construction.”

Additionally, OSHA (Occupational Health and Safety Administration) reports that one in five worker deaths last year were in construction.

The statistics only continue from there, highlighting the incredible need for construction safety equipment:

- Workplace fatalities from crane-related did fall to their lowest level in 2017 with 33 deaths. [BLS]

- Out of all worker deaths, construction, transportation and material moving workers account for 47%. [BLS]

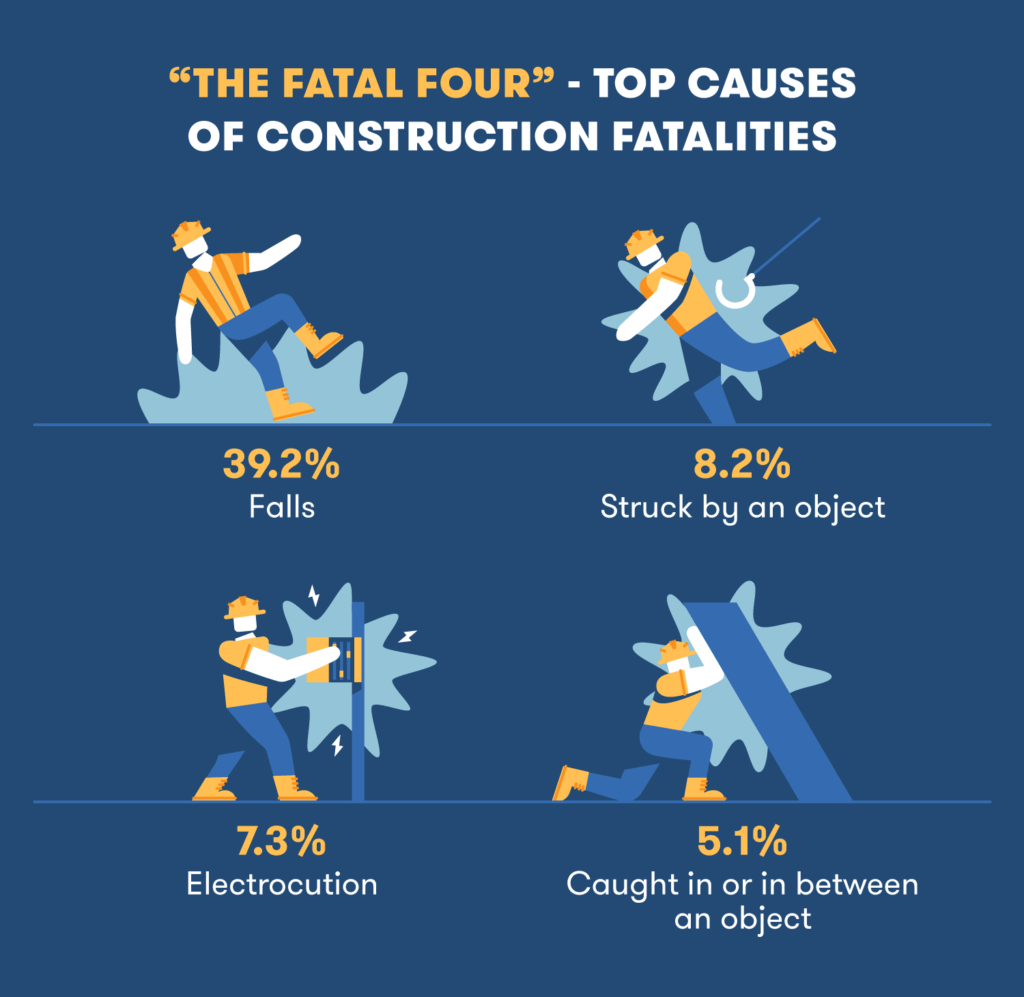

- The “Fatal Four” are the leading causes of the private sector working fatalities in construction – falls, getting struck by an object, electrocution, and getting caught in something or between objects. These accidents are also responsible for 59.9% of construction worker deaths. [OSHA]

- Companies that have 10 or fewer employees and anyone who is self-employed accounts for nearly half of all deaths on construction sites. [CDC]

- Of all industries, construction has the most fatal falls, accounting for 51% of all falls in the United States. [CDC]

- In a 45-year career, there is a 1 in 200 chance that a construction employee will die from a work-related incident. [PMC]

The above is alarming, yes, but it doesn’t underestimate the asset the construction industry serves. And it certainly doesn’t solidifies the need for effective construction safety equipment.

To most of us, it seems unlikely that the numbers of accidents and fatalities should grow at the current pace, especially considering the availability of advanced protective gear. And of course, regulatory safety requirements.

We highlight everything you need to know about construction safety products.

Prevention, Protection, and Professionalism

Before we talk about the types of accidents that occur at construction sites and discuss the construction safety equipment required by law, it’s important to talk about accident prevention.

Let’s get one thing straight: you can’t prevent all accidents. No matter how hard you try. You can supply the best equipment, the most reliable materials, and a perfectly safe construction site according to all regulations and recommendations. But you simply can’t avoid two things: bad luck and human error. Because all humans err and Murphy’s law trumps even the basic laws of physics. Your best bet is to and try and minimize the damage by equipping your workers with adequate protective gear.

It’s also a great idea to hold regular team safety meetings. Some workplaces do this daily, especially if high-risk work is on the agenda. Employees need to be reminded to remain focused and all relevant issues should be raised and addressed.

This doesn’t mean prevention and safety training is not important. Quite the contrary. Educating your employees, and giving them the skills to prevent accidents, is as critical as providing them with hard hats. The best thing you can do as part of your construction safety products, it’s to educate your employees. It’s part of the professional process, heck, it is the professional process, not to mention it’s required to maintain regulatory safety compliance. But we’ll get to that challenge later.

Beyond the Most Common Accidents in Construction

It’s time to get to know the enemy. And get to know our “weapons” in this fight for your employee’s safety.

According to OSHA and the BLS, the leading causes of worker deaths in the construction industry were falls, electrocution, struck by an object, and caught-in/between. These are dubbed “The Fatal Four”, and with good reason. They were responsible for more than half (59.9%) of all reported construction worker deaths in 2017 in the United States.

- Falls – 381 out of 971 total deaths in construction in CY 2017 (39.2%)

- Struck by Object – 80 (8.2%)

- Electrocutions – 71 (7.3%)

- Caught-in/between* – 50 (5.1%)

(*This category includes construction workers killed when caught-in or compressed by equipment or objects, and struck, caught, or crushed in collapsing structure, equipment, or material)

These are causes for accidents resulting in immediate (or almost immediate) death or injury. But what about safety hazards that cause long-term damage and can lead to impairment? For example, regular exposure to loud noise can cause hearing loss, and inhalation of toxic fumes can lead to respiratory disorders of all kinds. While these don’t create immediate concerns and casualties, personal protective equipment (PPE) is required by OSHA regulations for the construction industry. The list for construction safety equipment just never seems to end, does it?

A strong safety culture doesn’t have to be an impossible mission!

Join hundreds of construction companies who choose Connecteam to raise safety standards!

OSHA’s Regulations On Construction Safety Equipment

The standards and regulations document for the construction industry by the American Occupational Safety and Health administration is a tediously long one. It covers everything from safety standards for on-site equipment to instructions on handling hazardous materials and erecting steel structures.

We strongly recommend you take the time to review the linked document above. Not just for catching up on requirements and demands for safety compliance but also to check if there’s any potential safety risk you may have overlooked in planning your safety equipment purchases. Even if you have an onboard construction safety expert (how fancy), familiarizing yourself with the regulations and recommendations is important. Plus, you never know if you’re dealing with outdated construction safety equipment or construction safety products, so we think it’s a good idea to give the document a read – when you’ve got some spare time!

If you don’t have the time to look it over now, not to worry, cause we’re here to tell you that Subpart E is worth lingering on. It details the requirements and demands for personal protective equipment (PPE). However, the section is so hard to read we’re guessing it was written by lawyers and it also doesn’t include what we really need: Tips for selecting the basic protective equipment your construction workers need.

PPE Construction Safety Equipment

Personal protective equipment can be divided (roughly) into 2 categories – employee-owned and employer-owned. Regardless of ownership, regulations demand that you, as an employer, take responsibility for the quality, functionality, and hygiene of your employee’s own PPE.

The best way to ensure employee-owned PPE quality is to provide your workers with a list of recommended brands and vendors. Alternatively, you can arrange for a discounted purchase of compliant equipment for your employees.

Not all the jobs on the site are the same. For example, the boots an electrician needs are not the same boots a machinery operator needs. When performing your construction site hazard evaluation, be sure to take into account the different requirements of each role before selecting your preferred solutions.

Eyes and Face Protective Gear

“Not the face! Please! Not the face!” – that’s our battle cry. We like my face pretty and my eyes sharp. And so do your employees. It’s fairly obvious why protective eye gear is required when welding, cutting, grinding, nailing, or working with chemicals. But no one wants to get unwanted stuff in their eyes and face. Pretty much every tool out there recommends using protective eyewear when using it. Because it’s all fun and games until someone loses an eye. And then sues you.

Where to start looking: Top 10 Best Safety Glasses of 2016 (Comparison & Reviews)

More tips & recommendations: Choosing the best protective eyewear, OSHA Protective Eyewear Regulations

Safety Footwear

The basic compliance requirement in construction is that worker footwear is non-slip and puncture-proof. Since construction sites are often full of heavy things that can fall and break one’s toes, safety-toe footwear is highly recommended.

If you’re worried these features might make the boots too heavy to wear comfortably, you might want to invest a bit more in getting shoes with composite protection components. They are lighter, but provide the same level of protection.

Where to start looking: Top 5 Boots for Construction Workers

More tips & recommendations: Protective Footwear Requirements

Hand Protection Gear

When you talk about something fitting perfectly, it fits “like a glove”. So obviously, you want your gloves to fit. It’s not just about how comfortable they are to wear, it’s also about how suitable they are for the job (pun incoming!) at hand. For example, concrete work demands rubber gloves. Welding work demands welding gloves.

Your basic work gloves can only do so much against corrosive chemicals or sharp tools, but they are a must-have for anyone handing construction materials or equipment.

Where to start looking: Superior Glove – a manufacturer that focuses specifically on the construction industry and offering all the glove types you might need.

Worth a read: Cut-resistant hand protection myths busted

Head Protection

For most people, the first object that comes to mind when discussing construction safety is a yellow hard hat. Even kids know it, thanks to Bob the Builder. Wearing protective headgear is demanded on construction sites by regulation just about everywhere in the civilized world. Heavy things have a bad habit of falling in construction environments, and everyone knows it.

So most commonly the problem isn’t the scarcity of hard hats at construction sites, but more often it’s their quality. Over time, plastic ages and becomes fragile, rendering the hard hat useless. Cracked or dented hard hats aren’t much good either, so it’s important to replace old hard hats with new ones. And of course – ensure your employees actually wear them.

Where to start looking: The 5 Best Hard Hats for Construction Workers

Worth a read: Impact to the head hazards by 3M (PDF)

Hearing Protection – Noise Reduction

Construction sites are noisy places. To avoid worker hearing loss in the construction industry, OSHA has in place clear regulations for the types of hearing protection required for employees at construction sites.

It’s a bit funny that there’s still a need for such instructions in a regulatory document, but section 1926.101(c) clearly states: “Plain cotton is not an acceptable protective device.” A more up-to-date guideline would also include earphones as unacceptable replacements for hearing protection PPE.

It’s important to note that OSHA updated its guidelines for ear protection, and you should ensure that the equipment you are purchasing is compliant with the 2016 noise level blocking requirements.

Where to start looking: Best ear defenders for construction

More tips & Recommendations: The Ultimate Construction Ear Protection Guide

Respiratory Protection

Even when you’re not working with toxic chemicals or hazardous gasses, a respirator is necessary to keep your nose, throat and lungs clear of dust and debris at the construction site.

Of course, different respirators are needed for different purposes, and OSHA has detailed guidelines about what types of PPE are required and for what conditions.

More tips & recommendations: Respiratory Exposure Hazards [PDF] by 3M

Construction Compliance And Communication On The Go

Now here’s the rub. It’s one thing to understand the safety is imperative. It’s a completely different thing to enforce safety regulations. However, as an employer/manager it’s your duty to enforce safety regulations.

Compliance becomes especially challenging when you have a dispersed and diverse workforce. If you want these employees to comply with safety regulations and follow them to protect themselves? You need a solution that will be accessible and easy to use.

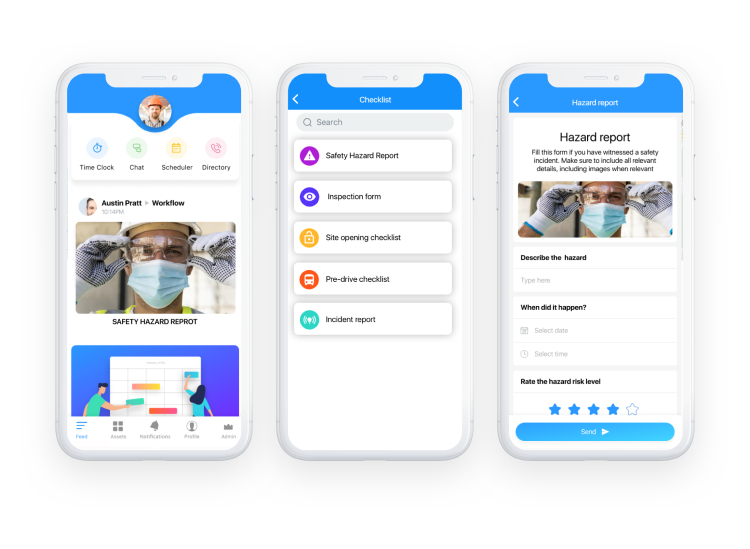

One such solution is Connecteam’s platform, an all-in-one mobile app solution for businesses. You can create your own branded app to make safety protocols and regulations readily available and up-to-date for your employees. On top of it all, you can also create time tracking, job scheduling, communication tools, mobile-first checklists, forms and reports, and more.

Listen to how a construction company with 200+ employees utilizes Connecteam for daily internal communication & engagement!

Safety, especially managing construction safety equipment, is the most important aspect when it comes to the construction industry, with Connecteam:

- On The Go Reporting so your crew can send reports straight while out in the field, and it’s delivered to the relevant officer or supervisor. This allows you to evaluate and respond to the situation in real-time.

- Examples include: safety hazard observation report or an incident report.

- Digital Resources make it easy to keep and manage all safety protocols, tips, and resources at any time.

- Examples include: ‘lessons learned’, incident findings, and periodical safety tips.

- Ongoing Safety Training keeps managers and safety officers in the loop so they know how their crew is coming along.

- Examples include: courses or quizzes – send a reminder to anyone who didn’t finish a mandatory session.

- Safety-First Communication allows you to easily communicate safety-related updates and protocols as they unfold.

- Examples include: incident finding reports, procedural updates, risk factors like rough weather conditions.

You might be also interested to read our round-up of the best construction workforce management software 2025.

There are many solutions that can help you manage and communicate with your workforce but few are meant specifically to match the specific needs of an on-site construction team.

Bottom Line On Construction Safety Equipment

Sometimes we think one of the hardest parts of managing construction is trust. At the end of the day, you need to entrust your employees not only with their job but also with the safety of their coworkers and their own.

You will probably never stop worrying about potential dangers to your crew (and as a result, to your business as well). But equipping your workers with the proper gear, knowledge, and skills to perform their job safely? Will help you sleep much better at night so that during the daytime you can focus on your job.