Toolbox talks are the perfect opportunity to go over safety hazards and procedures with your crew and ensure everyone is on the same page at the beginning of each workday. We’ve lined up 12 safety meeting topics you’ll definitely want to include to help mitigate risks and keep everyone safe.

Construction sites are notorious for their high number of safety hazards and job site accidents. And so, while workplace safety is critical for any business, it takes on even more importance in the construction industry.

Holding regular construction safety meetings is a vital part of any construction company’s safety program and an invaluable tool in protecting your employees and keeping your company compliant.

In fact, companies that hold daily safety toolbox talks reduce their total recordable incident rate by 85%.

But what construction safety topics should be a priority? Based on where the industry is heading in 2022 and beyond, here are some of the most essential construction safety meeting topics to tackle.

What Are Safety Meetings and Why Do They Matter?

In the construction industry, a safety meeting – also known as a “toolbox talk” – is a short safety meeting to address hazards, discuss best practices, and reinforce safety requirements before employees beginning their workday at a job site.

A frontline supervisor or safety representative is usually in charge of choosing the relevant construction safety meeting topics to present to your workers. These meetings can be as short as five minutes and should ideally not take longer than 10 to 15 minutes to make sure your crew stays focused throughout. You can conclude toolbox talks with a review or quiz to ensure your workers’ understanding, but that isn’t always necessary.

Safety meetings consistently communicate safe behavior with your team on a job site.

Such talks are also vital in helping your construction team to:

- Identify safety hazards, including those unique to a particular job site.

- Avoid injuries and deaths.

- Increase awareness on the importance of safety on the job.

How Often Should Safety Talks Be Carried Out?

Toolbox talks are often held before the start of every work shift in the field, while many construction companies choose to have these talks weekly. While there are no set guidelines on how often safety meetings should be held, they are generally more effective when carried out daily or weekly, as opposed to long periods of time between talks.

Especially since it only takes up a few minutes each day, making the most of your toolbox talks can positively impact job site safety.

What To Discuss During Your Construction Safety Meetings

-

Personal protective equipment (PPE)

-

Hazard identification and communication

-

How to prevent slips, trips, and falls

-

Fall protection

-

Falling objects

-

Lifting, carrying and handling objects

-

Electrical hazards

-

First-aid and emergency protocols

-

Fire safety

-

Lockout/tagout procedures

-

Hand and power tools

- How to select the appropriate tools for each task or job.

- How to examine tools for any damage before use.

- The correct operating procedures for each instruments.

- How to identify environmental issues that can affect tool safety.

- When and how to correctly use the proper PPE for relevant devices.

-

Open Forum for Concerns and Suggestions

As far as the most crucial construction safety topics go, personal protective equipment (PPE) is at the very top of the list.

Wearing the right PPE can help mitigate the damage done if there is an accident. And, on some occasions, following suitable safety protocols doesn’t mean anything if employees aren’t wearing the proper protective equipment.

It’s, therefore, up to every employer to provide the right PPE for workers based on their performing tasks. Management also has to give instructions on when and how to wear certain forms PPE.

Frequent construction toolbox talks are necessary to ensure that construction workers know PPE’s what, when, where, how, and why. Mark this on your to-do list for your next construction safety meeting topic.

While all work sites have safety hazards, each job site is different, with its unique surroundings, equipment, people, and working conditions. Therefore, it will always be essential for your construction workers to understand the hazards in each workplace.

Every time workers set foot on a new construction site; there should be a safety meeting to discuss the existing hazards and how to mitigate these. If new dangers or new ways of mitigating these are discovered, there should be a toolbox talk to bring everybody up to date.

Construction toolbox talks should also encourage workers to share any hazards they’ve discovered or close calls they had while working to raise awareness and learn from any near misses on the construction site.

Slips, trips, and falls are among the most common causes of injury on construction sites. Most of the time, such accidents occur because somebody was careless or distracted while walking.

On construction sites, it’s crucial to remain vigilant and aware of one’s surroundings, more so than at other workplaces. Not only are safety meetings on construction sites needed to remind workers to be careful, you can also share information about what surfaces might be slippery, what type of footwear is best to wear, and other tips that can help prevent careless slips, trips, and falls.

And so, discussing this construction safety topic during your toolbox talks can help you to reduce or eliminate such accidents.

Falls are amongst the Occupational Safety and Health Administration’s (OSHA) top four causes of construction fatalities. Each day, thousands of construction workers fall on the job site. The most common cause of falls is a combination of poor work conditions and poor decisions, but it can also occur due to PPE failure.

This is why fall protection warrants dedicated safety meetings and why no detail is too small to cover with employees.

These toolbox talks should discuss ladder safety, proper PPE, and safety measures that must be followed whenever employees work at heights.

It’s natural for people to be nervous or uneasy when working high above the ground, especially if they don’t have much experience doing it. Going over everything your workers need to know about fall protection can put everyone at ease.

There are many objects that aren’t always being controlled at a construction site, which is why falling objects are among the most common causes of job site injuries. And it doesn’t have to be a large object; something as small as a bolt could cause physical harm or damage equipment below when dropped from a high point.

Yet, it is one of the most overlooked construction safety meeting topics.

For every new construction site, a safety meeting should be held to discuss the specific objects that could be swinging, falling, or rolling at any given moment so that workers can be on the lookout for them. Sometimes just knowing the hazards in your construction safety meeting can help keep workers safe and protected.

Take Safety To The Next Level With Connecteam

Tons of managers are turning to Connecteam’s all-in-one employee apps, to deliver safety awareness right where their employees are. Join them now!

If it’s not a falling object or a careless fall, most construction injuries are back injuries – caused by trying to lift or carry heavy objects. Of course, most construction workers are strong and capable of lifting and carrying heavy objects.

It may seem like an obscure construction safety topic, but your crew still needs to understand the proper way to lift items in an ergonomically sound way to reduce the risk of back and musculoskeletal injuries.

It never hurts to have construction toolbox talks that focus on proper lifting techniques and when it makes sense to use multiple people or machinery to lift and carry items.

The longer employees go without being reminded about proper technique, the more likely they are to get lazy with their methods and rely only on their strength to lift items.

By holding frequent safety talks about proper lifting techniques, employees will always be aware of the right way to handle heavy objects.

Even though electrical mishaps aren’t as common on construction sites as falls, electrocutions are among OSHA’s fatal four as they happen frequently and are often deadly when they do. In addition, exposed wires or electrical damage can cause fires and serious injuries.

It is, therefore, such a severe hazard that the construction safety topic of electrical safety warrants frequent toolbox talks.

Construction workers need to know how to detect damaged or exposed wires and understand what can go wrong if they come into contact with live electrical equipment. Even if your employees are already familiar with this construction safety topic, go over it to refresh everyone’s memory and teach new workers.

Obviously, the point of construction toolbox talks is to prevent accidents and injuries from happening in the first place. But it never hurts to give employees a refresher on how to respond just in case there is an injury or some kind of emergency. Therefore, construction companies should give every employee basic first-aid training to ensure that there is always someone nearby who can perform first-aid if someone gets hurt.

There are a variety of injuries that are common on construction sites, including broken bones, burns, abrasions, and heat stress that require some form of first aid while waiting for paramedics to arrive.

Even if the odds of something serious happening are slim, it’s always best for workers to be instructed on how to respond to an emergency.

Many construction sites are at risk for fires between electrical equipment and flammable materials. Each year, fires cause many deaths and injuries on construction sites, resulting in hundreds of millions of dollars in property loss and damage.

As a fire can break out at any time, it’s best to address common causes for fires on construction sites, educate your workers on what they can do to prevent them and what to do in case one does occur. Also, share the importance of vigilance at the worksite.

Every construction site has machinery and equipment that needs to be serviced occasionally. Therefore, discuss the lockout/tagout practices and procedures necessary to disable these items to prevent the release of hazardous energy during servicing and maintenance activities in your toolbox talks.

Tagouts also help track who last worked on the machinery or equipment and any important details. Your construction safety meetings are an ideal place to go over this safety topic in construction around these essential practices.

Standard construction equipment and machinery can pose a risk without proper training and use. Employers can use safety meetings as an opportunity for a quick refresher course on using familiar tools, training on how to use new devices or a combination of both.

Subjects for such meetings can include:

Last but not least, companies should hold construction toolbox talks that are essentially open forums for employees to bring up topics they want to discuss. The more a construction company can get workers engaged in safety protocols, the safer everyone will be.

Allow employees to voice safety concerns or offer solutions on how safety can be improved.

Construction workers are the ones on the frontlines who might be putting their safety at risk every day, so they should have a good understanding of how safety can be improved. Give them an opportunity to take charge during a toolbox talk and discuss what they feel is important. This can also be a good time to get their feedback on any potential changes that are being considered because that feedback can be invaluable before any safety changes are made.

Include them in your safety training planning as well. The last thing you want is high turnover over something that could have been prevented or taught.

Frequently Asked Questions On Construction Toolbox Talks

Construction toolbox talks must be run frequently, ideally, once a day, at the start of the day. But if once a day isn’t possible for your business, then once a week is also good for scheduling. Generally, this frequency ensures the talks are effective.

Safety toolbox talks should typically run for 10 to 15 minutes. They could be longer, but the aim is to keep them brief.

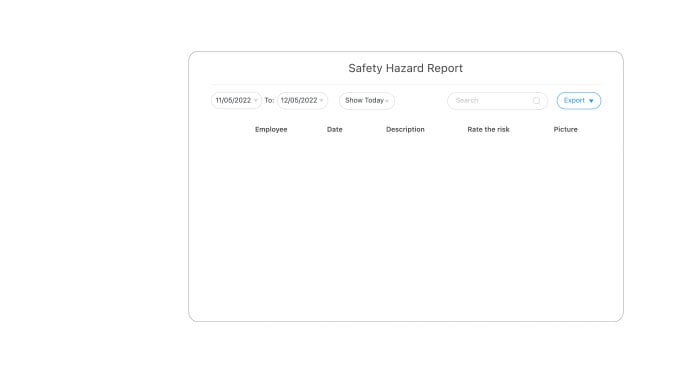

Your safety toolbox talks should be documented in detail. Use sign-in sheets and include the date, time, attendance, topic, discussion notes, questions, and anything else that may have arisen.

The most senior or experienced team members should lead the construction toolbox talks at your upcoming construction safety meeting topic.

Using presentations, videos, demonstrations. In short, using any method that is engaging and helps convey information clearly and rapidly.

Each construction safety meeting topic should cover a single topic at your next. Remember, they are short sessions, so you don’t have long to convey all the information.

Don’t forget about safety products as a construction safety meeting topic either.

Typically most construction teams rely on the Connecteam all-in-one construction app to ensure direct access to construction safety topics at any time.

One of the best features of this is the knowledge center and library. Simply upload a video recording or chapters to read and encourage your crew to review this frequently to ensure your construction toolbox talk is fresh in their minds.

You can even issue a quiz to ensure they understand the material covered in the construction safety meeting topic.

Wrapping Up Construction Toolbox Talks

We recommend keeping an eye on OSHA’s toolbox talks for your next construction toolbox talk or if you need some ideas on construction safety meeting topics.

Remember that construction toolbox talks are all about building a safety culture. So the more often you embed construction toolbox talks, the better your workplace and employee safety will be.

Take Safety To The Next Level With Connecteam

Everything you need in a single app, accessible at any tim