If you own a retail business and need a more efficient way to take physical counts of inventory then this is the blog for you! Here are 5 easy steps you can implement today to make counting inventory a walk in the park!

The dreaded inventory check… It can take hours and even days to count all inventory, and your employees probably dread it just as much as you do.

A regular inventory count, as annoying as they are, are a necessary part of any retail business owners day-to-day.

The last thing you want as a business owner is shrinkage in your retail due to irregular or inconsistent inventory checks. Shrinkage, if left unchecked, can lead to massive amounts of money being wasted due to inefficient inventory checks.

Additionally, if you don’t know what needs to be reordered and restocked, you may be dealing with unhappy customers that can’t order what they want and end up buying from your competitors.

But what exactly is an inventory check and how can you make it more efficient and dare we say… fun? Let’s jump right in…

What Is An Inventory Check?

An inventory check is the only way businesses can know exactly what they’ve ordered, what they have, and what is needed.

James Woodruff, a management consulting expert, notes that inventory checks “includes the efficient management of purchasing, receiving, warehousing, tracking, shipping and reordering — and it’s how you maximize the return on your inventory”.

When doing an inventory check there are some aspects you should focus on:

- Where products are located in the store.

- Quantities of each different product.

- Condition of products.

- If items are perishable, then dates on these perishable items should be noted.

- Number of products in the warehouse.

- Number of products that need to be reordered and restocked.

These are just a few examples of what should be focused on when doing an inventory check.

Regular and consistent inventory checks and physical counts of inventory are essential to your business’ success and can keep you from wasting thousands of dollars.

What’s The Difference Between Physical Counting And Cycle Counting?

Good question! Cycle counting requires employees to create a cycle of counting through the inventory. Forbes describes that “regular cycle counts allow you to catch small discrepancies as soon as possible. Cycle counting refers to a style of perpetual inventory taking for subsets of your wares”. But it isn’t necessary to do cycle counting on all your inventory, cycle counting is usually done on seasonal or frequently sold out inventory.

Physical inventory counting demands that employees physically count each and every item, also on a regular basis. This usually means that employees will have to stay late during these inventory counts and go through each item to create an accurate and thorough inventory count and record.

Why Are Physical Counts Of Inventory Essential?

If you’re a retail business owner, especially a small retail business owner, then proper inventory management is crucial to your business’ success and bottom line.

Derek Broman, CEO of Discount Enterprises LLC, notes that “correct inventory tracking and management has helped [him] to use [his] physical storage space and transportation resources more efficiently, identify trends in consumer desires and popular products, and proactively prepare to meet stocking needs”.

Physical counts of inventory are essential for the following reasons…

- To ensure that no items have been stolen or damaged. While inventory may go missing or become damaged by customers, unfortunately employees can also steal and damage items. Performing regular inventory checks will help deter employees from stealing as they know items are being regularly counted. Additionally, if an employee breaks or damages an item, they are more likely to take accountability for it because they know inventory is regularly being checked.

- To order more items that need to be restocked. How can you know what items need to be reordered if you haven’t physically counted your inventory? That also means checking how many items are available on the floor and in your warehouse as well.

- To understand consumer trends and wants. By collecting data and on what items are frequently being sold out and reordered, you can better understand what your customers wants and needs are to increase your profits!

- To ensure your ordering and restocking quantities are what your business actually needs. Without doing a physical inventory check, you may find yourself ordering the same quantities and items over and over and not selling them. Why waste time and money on items or products that aren’t actually selling?

- To ensure that suppliers are delivering items that aren’t damaged and the right amount is being delivered. People are human and we all make mistakes, even suppliers. It’s important to do inventory checks — even on the inventory that is just received, to make sure that all items can be accounted for and that they aren’t damaged.

By conducting regular and frequent inventory checks you can avoid all these issues, save time, and money! Furthermore, if you’re conducting your inventory checks manually, with pen and paper, then you’re wasting a ton of your employees’ time and it can be full of errors and mistakes!

We’ve broken down how to take an inventory count in 5 easy steps and what technology you can use to improve the way you count and record inventory.

Take The Headache Out Of Inventory Counts With Connecteam Today!

Learn More

How To Take Inventory Count In 5 Steps

There are a few ways to reduce the time it takes and to increase efficiency when it comes to counting inventory. Here are 5 easy steps you can implement today to improve how you take inventory count.

-

Use An All-In-One App To Take Inventory Count

-

Plan In Advance

-

Decide How Often You Check Inventory

-

Have A Designated Space

-

Assign The Right Team Members

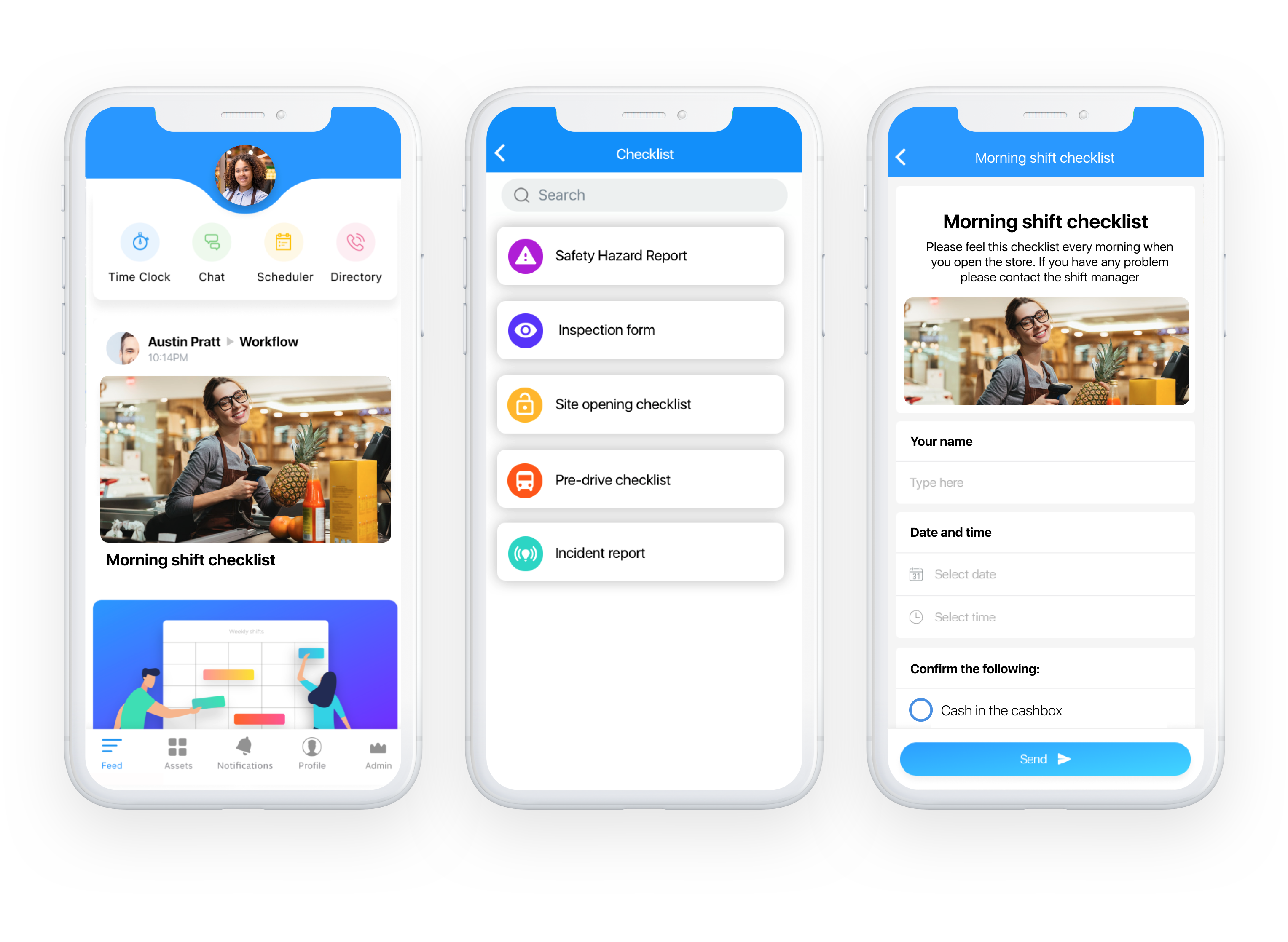

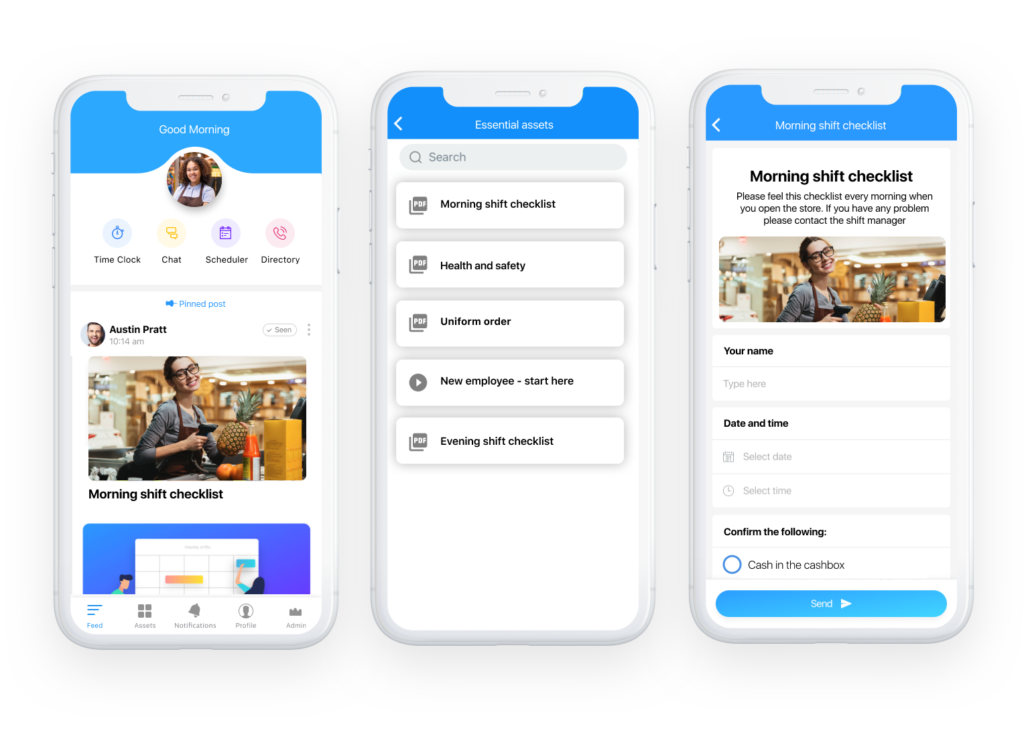

First of all, to count and record all your inventory, your employees will need the right tools and technology to make their job more efficient. By investing and implementing an all-in-one employee management app, like Connecteam, you increase employee accountability and efficiency with inventory checklists.

While Excel is also good for inventory management, it’s impossible to attach images or videos. With Connecteam, you can require employees to include images and even electronically sign on completed inventory forms. For example, if items are damaged, you can instruct employees to take a picture of the damaged items to attach to the inventory count.

With Connecteam, employees can digitally fill out inventory checklists and forms directly from their mobile device at the end of each day to ensure accurate inventory counts daily!

Make Inventory Counting Easy & Efficient With Connecteam Today!

14-day free trial, no credit card required.

Now that your employees have accurately counted and checked the inventory with the help of the right tools and equipment, it’s time to plan your restocking and reordering in advance. Check to see what items sell out quickly, which items are standing on shelves for a long period of time, or if you need to order anything in time for the holiday season.

By doing so, you can make better, more informed decisions about what inventory is selling well, what should be reordered, and what your customers and clients really want.

Additionally, once you have a better understanding of quantities of items that need to be restocked, you can then strategically place items around the store and in your warehouse to make inventory checks easier and more efficient.

This truly depends on the type of inventory you have. If you have items that are perishable, then conduct daily inventory checks to ensure items aren’t going bad and can be sold prior to their expiry date.

If your items are non-perishable, frequent weekly or biweekly inventory checks are recommended. It’s important to do inventory checks often to ensure employees and customers aren’t stealing, to increase employee accountability, and to increase supplier accountability.

Create a designated space for employees to store and count inventory. Whether that’s on the sales floor or in the warehouse, providing your employees a designated space will make taking physical counts of inventory much easier.

It’s important when assigning inventory count to a team that you choose the right people.

Pick a couple of new employees, but most of the team should be veteran employees. Experienced employees are great for the job because they have been with the business for a good amount of time, are familiar with all the different types of inventory, and can even teach some rookies how to properly get the job done.

The Bottom Line: How To Take Physical Counts Of Inventory In 5 Easy Steps

It should be pretty apparent by this point in the blog that physical counts of inventory are a necessary part of owning and operating a retail business.

Regular physical inventory counts helps managers and business owners understand if inventory has been damaged or broken and by whom, to better understand what inventory needs to be regularly restocked, what customer trends and wants are, to ensure you’re ordering the right quantities of stock, and to guarantee that suppliers are delivering correct and undamaged products.

To make inventory counts more efficient and accurate then you should invest in the right tools and software to help get the job done right. With Connecteam, inventory management can be easily conducted throughout multiple retail store locations. Create inventory checklists, have employees electronically sign off on inventory forms, and even include images and videos of damaged and broken products for inventory record keeping.

With the right inventory management software, like Connecteam, tackling the previously mentioned 5 easy inventory counting steps will be even easier for your employees.

Join Thousands Of Retail Companies That Trust Connecteam To Count Inventory & Manage Employees Today!

14-day free trial, no credit card required.