No more second guessing. We share nine must-follow tips on how to start a manufacturing business to ensure success from day one.

I don’t have any personal or strong desire to run a manufacturing business.

But, here’s what I do know, if you can make quality products and manage the selling of those products, starting a manufacturing business can be a lucrative endeavor.

Especially, when there’s always a demand for quality manufacturers because it’s not a skill set everyone has.

So, if you’re in the business of making money and doing what you love, you need to do a little thing I love…research!

The key is knowing how to start a manufacturing business before you even get started.

- What are the steps you must take, the decisions you have to make, or the challenges that await you?

- Equally important, where can you turn to for help when you need it?

To help give you a better understanding of how to start a manufacturing business and turn it into a success, we put together this step-by-step guide to use as you begin your journey.

-

Perform Market Research

-

Pick Your Niche

-

Write a Business Plan

-

Get Funding

-

Find the Best Space

-

Purchase Equipment

-

Find The Right Digital Tool

- Increase workplace safety with a digital catalog of training materials and resources, share videos, start quizzes to ensure knowledge, and more

- Whether it’s logistical, operational, or fun internal communication, you’re covered with group or 1:1 chat, a social feed, and push notifications

- Ensure accurate payroll with a GPS time tracking app with a simple clock in and out function, manage time off requests, and export timesheets to QuickBooks Online or Gusto for accurate payroll.

- An employee scheduler, for teams or individuals, is easy with drag and drop, recurring shifts, templates and more

- Create “read and sign” forms for compliance

- Automate daily processes when employees can send in reports from the field like hazard protocols, machine cleaning forms, incident report, repair order, etc.

- Don’t let employee engagement drop, share live polls, implement a suggestion box, and share surveys to gain feedback

-

Hire People to Make Your Product

-

Put Procedures in Place

- How are you going to organize workspaces?

- How are you going to organize inventory?

- Are you up to speed on workplace safety? What rules do employees have to follow to ensure workplace safety?

- How are you going to guarantee that you meet production goals?

- What’s the employee handbook going to cover?

- Is there a code of conduct? What’s in it?

-

Promote Your Business

The manufacturing industry is one industry where a significant amount of research is required before starting a business. The industry is so diverse and complex that you’ll get eaten alive if you try starting a manufacturing business without doing your homework.

The ultimate goal of market research is to find a gap in the market that your new business will be able to fill. Even if you have an idea regarding the products you want to make, you still need to perform market research to confirm that it’s a good idea and the best way to attack the market.

Remember that you don’t want to commit too early to a particular product or type of business. Make sure you do your due diligence and allow the market research to guide you.

Once you’ve performed an extensive amount of market research, you can select your niche or specialty within the manufacturing industry. There are so many products out there that the possibilities are almost endless. However, you have to use your research to figure out the niche where you can have the most success.

Naturally, your personal preferences, skillset, and work history will play a factor as well. But your market research should be the most important factor in nailing down your niche, whether it be electronics, industrial, pharmaceuticals, or any other potential niche within the manufacturing industry.

After you’ve narrowed down your niche, it’s time to get serious about starting a manufacturing business and write a formal business plan. This is where all of that market research you did at the beginning will come in handy.

In your business plan, you’ll aim to answer important questions about the products you’ll offer, the gap in the market that you’ll fill, the customers that you’ll try to target, and the competitors in that part of the market.

Your business plan will also include important financial information about how much it’ll cost to get your company off the ground and how long it’ll take until your business can start turning a profit. When it’s time to seek funding for your new business or bring aboard any partners, you will need to show a business plan that has answers to all of the more pressing questions related to how to start a manufacturing business.

One important thing to remember about starting a manufacturing business is that it won’t be cheap. Even if you have the experience and know how to start a business, you’re going to need outside funding to help you get off the ground.

This is why your business plan needs to be on point because investors will want to see your business plan before writing a check. This could mean getting a business loan from a bank or exploring private investors. Even if you know friends or family who want to help with an investment, you will need your business plan to put them at ease that your idea is viable and your business will be successful.

Of course, your business plan should also include specifics about how much money you’ll need to raise depending on your product and market. The general rule is that the more expensive your products will be, the more money it’ll take to get your business off the ground, which is something to keep in mind when looking for investors.

You’ll need to find a space that’s available to set up your warehouse.

This may sound easy, but it won’t be.

There are a lot of factors that go into selecting the right location, and we’re not just talking about something that will fit your budget. You will need a location that’s ideal for bringing in raw materials and then shipping out your final product.

Keep in mind that shipping is one of the biggest costs for any business, so a location that can reduce that cost as much as possible will be invaluable for your business. You also need to consider the size of the space for your operations.

Finally, your warehouse should be in a location that will help you to recruit a competent workforce.

After the site of your operations has been determined, you can start to fill that space with the equipment and supplies you’ll need.

Keep in mind that space is a key factor, and the machinery and equipment you purchase will depend on how much space you have at your disposal. It’s critical to purchase equipment that will fit the space and make sense for the floor plan you have in mind.

Of course, this is where your business plan and your budget come into play as well.

Having physical equipment is important, but when it comes to managing daily operations and ensuring employee productivity and happiness, you need to look for a digital tool.

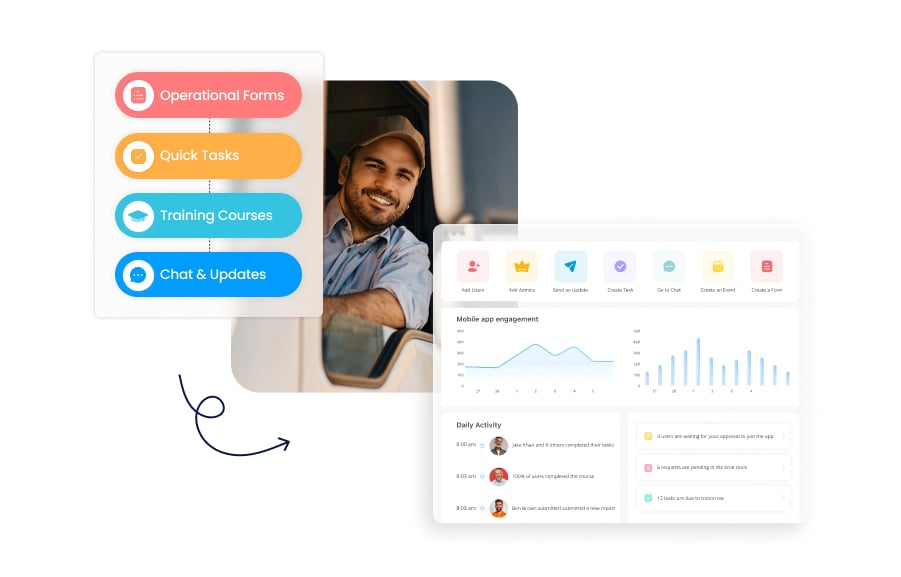

Many owners and managers in manufacturing turn to the Connecteam all-in-one employee app to do just that.

Why? For starters, Connecteam is easy to use, can easily scale with your business, has the best customer service around, can be customized, and is highly affordable.

Not to mention, it offers a robust set of features to ensure business success. For example:

And that’s just scratching the surface. If you’re serious about your business’ success, then you need Connecteam to scale and grow.

Build Your Business Up For Success With Connecteam

Free 14-day trial, no credit card needed

You’re not planning on making all of the products yourself, right?

Even if you’re a skilled manufacturer, you’re going to need a team of employees that you can train to do a majority of the work.

When you’re writing your business plan, remember to come up with a strategy for hiring a top-notch team. Think about the traits you want in employees. What qualities does the ideal employee possess? It’s not always going to be about skills and experience; attitude counts for a lot as well, especially with a new business that’s still trying to grow. You’ll want to hire employees who fit the type of culture that you’re trying to create with your business.It can be helpful to ask behavioral questions during the interview.

Another part of building that culture is creating procedures for your employees to follow. Successful manufacturing businesses will always have a plan in place.

The details of how you’re going to maximize your productivity need to be in place from Day 1 so that your employees understand the right and wrong ways to do things.

One of the last steps in starting a manufacturing business is being able to promote and advertise that business. It’ll be difficult to get off the ground using word of mouth alone. Your business might provide better quality work than competitors, but that doesn’t mean that your potential customers know that.

Nowadays, digital marketing is an essential part of promoting your business. You need to have a functioning website and a presence on social media.

Of course, traditional forms of marketing and advertising will also be effective for a new manufacturing business. It also helps to create partnerships with other businesses that will allow you to help each other out. If you can offer them something in exchange, try reaching out to other businesses that might be able to help you gain traction in the market.

Wrapping Up Starting a Manufacturing Business

At this stage, you have all the information you need on how to start a manufacturing business. You’ve done your due diligence and are ready to hit the ground running.

Remember that it’s just as important to hire a top team of professionals and to ensure you have the right digital tool in your backpocket as it is to choose your business location and market your business.

Good luck!