Mispricing your construction project can lead to cash flow issues, losses, and customer disputes. We share tips on how to price a job in construction accurately and strategically so you can run a smooth and profitable business.

Getting your pricing right is crucial to successfully executing construction projects. Underpricing can result in financial losses, project delays, cash flow problems, and more. And quoting too much can cost you customers and damage your credibility in the market.

Unfortunately, this isn’t uncommon. Many project managers and contractors mess up their estimates due to miscalculations, changes in project scopes, volatile market conditions, and other unpredictable factors. That’s why you must take a methodical and well-thought-out approach to your pricing strategy.

In this guide, we share how to price a construction job accurately and strategically in a few simple steps. Following these steps and our recommended best practices can help you make informed and well-rounded decisions when setting your projects’ price points.

Key Takeaways

- Pricing a construction job precisely is key to turning a profit and maintaining positive client relationships.

- Conduct a thorough analysis of project needs and estimated costs to get your pricing right.

- Pick a pricing model and set suitable payment terms that align with your company’s financial and customer relationship goals.

- Use construction management software to track costs, stay on budget, and review reports that can help with pricing jobs.

What Is a Construction Job and Who Sets the Price for It?

A construction job refers to any project that involves the building, repairing, or maintenance of structures, including residential homes, commercial buildings, roads, bridges, and infrastructure projects. A construction job typically encompasses several tasks—from site preparation, foundation laying, electrical and plumbing jobs, and structural work to finishing touches like painting and landscaping.

The price for a construction job is usually set by the contractor or contracting business wanting to do the project. They calculate the costs of labor, materials, equipment, and other overhead expenses. They then choose a suitable pricing model and present their proposed price.

This Might Interest You

Learn about the best contractor apps for contractors in our detailed review.

How To Price a Construction Job

Here’s a step-by-step guide to setting an accurate price for your construction job.

Step 1: Conduct an initial assessment

The first step in pricing is evaluating what you need to execute a project successfully. Here’s how.

Gather project requirements

Speak to the client, project owner, or construction project manager about the scope of work and objectives of the construction project. This could be building, demolishing, excavating, or other specialized tasks.

Additionally, obtain detailed blueprints, architectural drawings, and other specifications from the project’s architect or design teams to understand the scale and dimensions you’ll be working with. In some cases, you might consult your in-house design team.

Using your understanding of project requirements, create an exhaustive list of required materials, including quantities, types, and any particular brand preferences. Also, add any labor permits required and resources needed—manpower, equipment, machinery, and so on.

Conduct a site evaluation

Visit the site to understand the current landscape and terrain your team will be working with. Thoroughly assess environmental factors, weather conditions, existing structures, and other potential challenges you could face so there aren’t surprises later on.

For instance, imagine you’ve signed a contract without visiting the job site. When work begins, your team realizes the narrow roads make transporting heavy machinery and materials there challenging. This will complicate logistics and increase transportation costs, increasing overall project expenses. That’s why you must know this information before pricing the project.

Additionally, check the construction site for potential safety hazards. For example, a construction project at a height has an increased risk of workplace injuries, so you’ll want to account for additional insurance costs when pricing the project. Lastly, evaluate local regulations, zoning laws, and additional permit requirements and their associated costs.

Step 2: Estimate your total costs

Once you have a strong grasp of the job’s requirements and site characteristics, estimate your total job costs using that information. Most construction jobs require the following business expenses.

Material costs

Use your list of required materials to start obtaining quotes from multiple suppliers. Additionally, conduct your own research to identify current market prices, current and expected trends, and so on. Get a fair idea of costs per unit while accounting for any potential cost fluctuations. Finally, consider wastage, damages, and extra materials required for unforeseen events.

Labor costs

To estimate the costs of paying your construction team, break down the project into specific tasks. Estimate the different labor types—skilled, unskilled, specialized—and the labor hours required for each task. Calculate your basic labor costs by multiplying estimated hours worked x hourly rates for your workers. Make sure you list all types of construction jobs needed with different rates for different skills.

Account for additional labor expenses like taxes, workers comp insurance, benefits, and so on. These will be part of your total labor costs. Don’t forget to adjust for potential fluctuations in labor availability—for instance, based on seasons or local demand.

Pro Tip

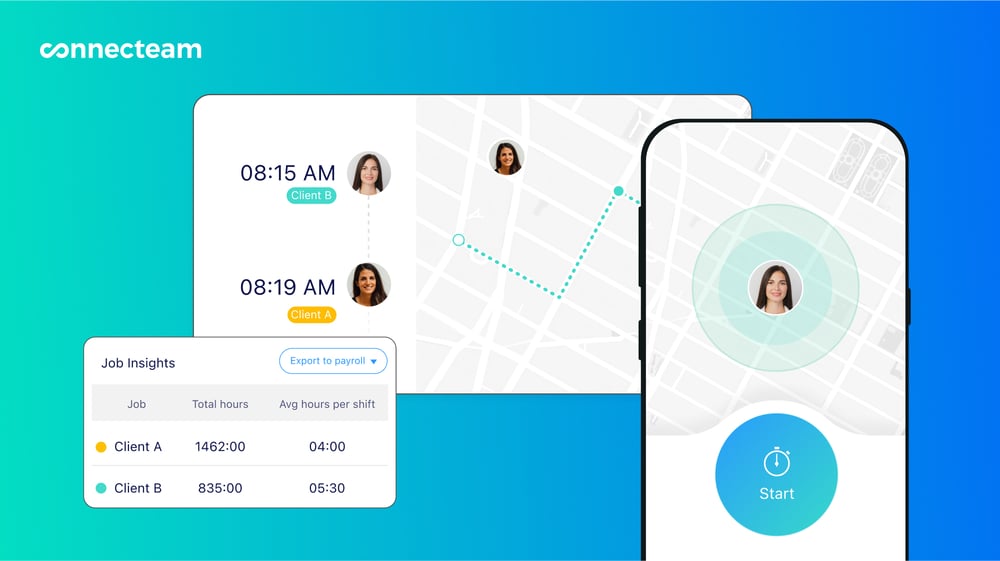

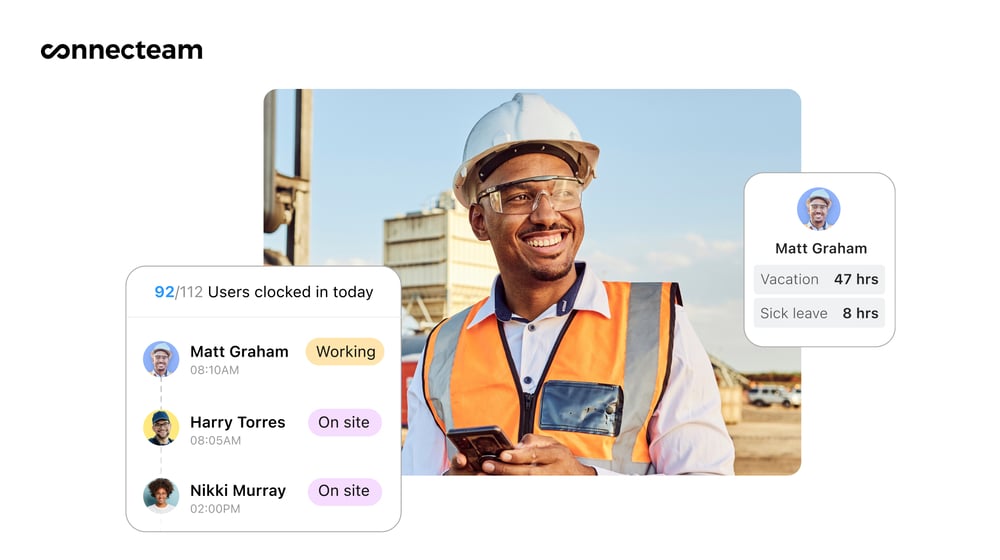

Use historical timesheets to estimate individual workers’ productivity levels and hours required for projects. Connecteam’s time clock for employees is a great way to keep tabs on your team’s working hours across different projects.

Subcontractor fees

You might need to hire subcontractors for specialized tasks like electrical work and swimming pools. Clearly define these tasks and obtain quotes from reliable subcontractors to make better cost estimates.

Did You Know?

Connecteam’s employee directory app is a great place to store contact information for workers, subcontractors, and other vendors. This way, you can quickly go through your contacts and reach out for quotes when needed.

Equipment and machinery use costs

Once you’ve compiled a list of necessary machinery and tools for the job, obtain quotes from equipment rental companies or suppliers.

Alternatively, estimate the costs of using equipment that you already own. Here’s a basic method for doing this:

- Purchase price: Consider the purchase price—for example, $20,000.

- Ongoing costs: Add maintenance ($500/year) plus other expenses like fuel and storage ($300/year) over expected usage time (5 years). ($500 + $300) x 5 = $4,000.

- Total cost: Add purchase and ongoing costs. $20,000 + $4,000 = $24,000.

- Depreciation rate: Consider the equipment’s lifespan (10 years). For a 10-year lifespan, it depreciates at 10% each year. After 5 years, it will depreciate 50%.

- Cost/project: If you plan to use it for 50 projects over 5 years before selling it, your cost/project is $24,000 / 50 = $480.

Permits and other fees

Consider seeking legal consultation to ensure you’re complying with regulations. In addition to considering consulting costs, determine expenses associated with obtaining the necessary licenses and permits to conduct construction works.

Overhead costs

Factor in ongoing operational expenses that aren’t directly tied to a project but are needed to run your business. For instance, include office rent and utilities, machinery and assets, worker salaries, and construction management software.

This Might Interest You

Read our detailed reviews of the 10 best construction management software for 2025.

Taxes and insurance

Speak to your certified public accountant (CPA) or tax advisor to understand applicable local, state, or federal taxes for undertaking this project. Additionally, obtain quotes from insurance providers for liability, worker’s compensation, and other required insurance.

Contingencies

Once you’ve assessed potential risks and uncertainties like harsh weather conditions and existing structures, add an appropriate contingency percentage to your costs so you’re covered if you exceed your original budget.

Evaluate the risk level for each potential issue, such as the likelihood of encountering harsh weather. Based on this risk assessment, apply a contingency percentage—typically ranging from 5% to 20%—to your total project cost. Higher-risk projects demand higher contingency percentages. Ensure your percentage is fair for the risk level.

| Expense | Estimated Cost ($) |

| Materials | 1,000 |

| Labor | 2,500 |

| Subcontractors | 1,500 |

| Equipment and machinery | 3,000 |

| Permits | 0 |

| Overheads | 1,500 |

| Insurance | 100 |

| Taxes | 400 |

| Contingency fund | 1,000 |

| Total Cost Estimate | 11,000 |

Pro Tip

You don’t need to calculate construction costs manually. Construction estimate software can streamline and automate the process.

Step 3: Determine your desired profit margin

In addition to covering the above job costs and business expenses, you’ll want to make a reasonable profit. Your profit margin is the percent of revenue your business makes after accounting for all costs.

A good profit margin keeps you motivated and your business running successfully. Here’s what to consider when determining your desired profit margin.

- Project complexity: Complex projects may warrant higher profit margins because they’re high risk, take more work, or require special expertise.

- Timeline and duration: Consider a higher profit margin to cover extended operational costs and market fluctuations for longer projects. On the flip side, urgent jobs on a quick deadline may also warrant higher profits.

- Client relationship: In long-standing client relationships or relationships you want to retain long term, consider accounting for a lower profit margin to offer your client a better price.

- Business owner salary: To pay a reasonable owner salary and invest the remaining profit back into the business, account for this salary either in labor costs or in your desired profit margins. The average US construction business owner’s salary is approximately $95,000/year.

Step 4: Choose a pricing model that aligns with your goals

You can choose from multiple strategies when pricing your construction project. Choose a strategy that feels fair to your clients while helping you achieve your business goals—like making a good profit, breaking into a market, or remaining competitive. These include:

Cost-plus pricing

This is one of the most popular pricing methods in construction. Estimate the total costs of running a construction job—including materials, labor, overheads, and more. Then, add your desired profit margin in dollar terms to arrive at the price you’ll charge your customer. If done correctly (and unforeseen issues don’t occur), this method will make you your desired profit.

For example, say your total estimated cost is $100,000 and your desired profit margin is 20% or $20,000 in dollar terms. Your construction job price would be $100,000 + $20,000 = $120,000.

Competition-based pricing

For this model, thoroughly research your competitors’ pricing strategies and price points and set a price that aligns with the competition. General contractors and companies with a broad range of services and customers commonly use this model. They adjust prices based on market rates, aiming to remain competitive without heavily focusing on premium or low-cost positioning.

For example, if competitors charge $100,000 on average, either stick with this or go slightly lower (like $90,000) to gain a competitive edge.

Pro Tip

Consider using competitor prices as a benchmark if you’re a new business and require more time to establish your own strategies.

Price skimming

Set high initial prices and adjust or lower prices based on market reception and feedback. Businesses offering highly specialized or innovative construction services might opt for skimming. They target clients willing to pay a premium for unique services or technologies.

For example, say you bid at $150,000 but potential clients say it’s too much. You could lower your bid to $125,000 and reassess based on new feedback.

Penetration pricing

This strategy calls for lower initial prices that can later be raised as a business gains demand and traction in the market. New entrants or small contractors who want to enter a competitive market, establish their brand, and capture market share use this model.

For instance, in a competitive housing market where homes are typically $200,000, you might price a project at $150,000/home to gain market share quickly.

Value-based pricing

In this pricing model, your price is based on what the customer believes it’s worth. Businesses offering high-quality craftsmanship, custom designs, luxury renovations, and so on may benefit from this approach. This is because clients seeking superior quality and unique features may be inclined to pay higher prices based on the perceived value of the finished work rather than the actual costs.

For example, you might price a luxury, eco-friendly office building at $300,000—which could yield you a 30% profit margin—since the customer is willing to pay that much.

Step 5: Decide on pricing terms

Once you’ve decided on the total price of your project, you must determine the payment structure—how costs are managed and shared between you and the client. Here are some structures to consider.

Lump sum

You provide a total fixed price for the entire project based on your estimates, and the client pays you in a lump sum. While this is simple to execute, you’ll assume the risk of cost overruns, unforeseen issues, or changes in the scope of work.

Cost-plus

In this structure, the client pays for the actual costs of material, labor, and equipment, plus an agreed-upon percentage for overheads and profit. It provides transparency and allows for flexibility but does require a certain level of trust between you and your client.

Guaranteed maximum price

Here, you commit to completing the project within a set maximum price. This way, you’re protected from overrunning costs to a certain extent. However, if your costs exceed this limit, you’ll cover the excess. This model offers certainty for the client and can enhance your client relationships, but it does pose financial risks for you.

Target cost contracting

This is a collaborative approach between you and your client. Both parties agree on a predetermined target cost for a project. If costs come under the target, both parties share the savings. Cost overruns are split between you and your client within specified limits.

Did You Know?

In most cases, you’ll negotiate the terms of payment with your potential clients before signing the contract. Are other employees in your company charged with negotiations? Consider using Connecteam’s employee training software. Create and deliver negotiation skills training courses to help them negotiate terms that meet your goals and align with client needs.

Step 6: Sign the contract

Once you’ve pitched and agreed upon a final price and pricing terms, you and your client can sign your construction project agreement. Having an attorney go over the terms before you proceed might be a good idea.

Did You Know?

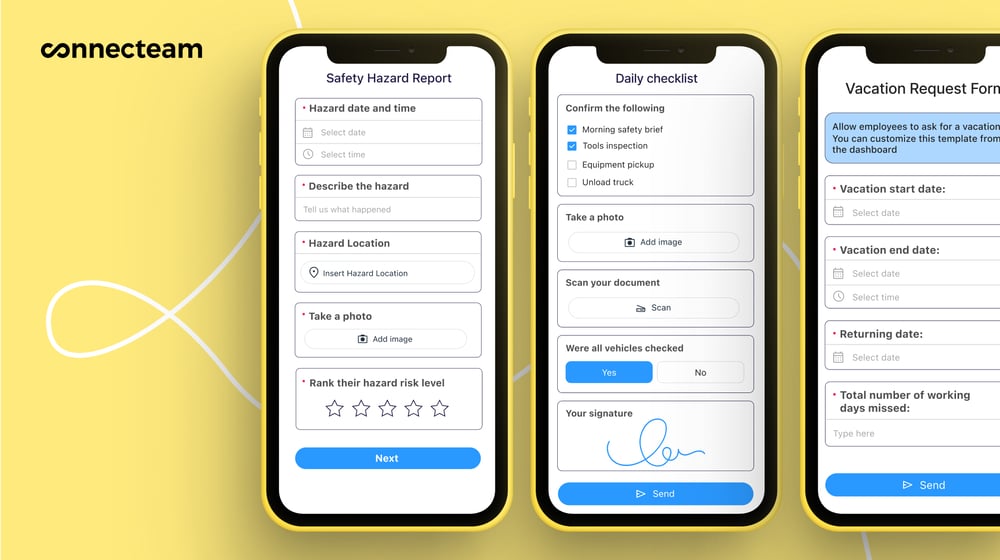

You can use Connecteam’s digital forms to create and update custom forms—including contracts—quickly and efficiently. You can store these in your company knowledge base to access them easily from anywhere.

How To Price a Job in Construction: Best Practices

Follow these best practices when setting your price for construction jobs.

- Use tools like a calculator, Excel, or budgeting software instead of making manual calculations. It’ll save time and reduce errors.

- Double-check your calculations or have someone reliable on your team go over them. Even little mistakes can have disastrous consequences.

- Keep close track of your budgets and let your clients know immediately if you’re expecting to exceed them.

- Continuously assess your pricing strategy to see if your estimations, models, and payment terms work well. This way, you can spot potential issues and fix them before pricing your next job.

- Use good construction management software like Connecteam to keep your projects on schedule, on budget, safe, and compliant.

Bottom Line on Pricing a Job in Construction

Knowing how to price a job in construction accurately and strategically has numerous benefits. It reduces the risk of overrunning costs, increases profitability, and creates a positive impression on customers. But, getting the pricing right isn’t easy. There are many factors to consider, and companies often run into unforeseen challenges.

Conducting a thorough analysis of job requirements is the first step to precise pricing. Further, estimate every expense you expect to incur. Finally, choose a pricing model and payment structure that align with your company’s goals while suiting your client’s preferences. This way, you can run a successful business and build trust and credibility with your customers.

FAQs

What is the difference between a project’s price, estimate, and budget?

A project’s price is the amount you quote and charge your customers. An estimate refers to the total project cost you expect to incur. Finally, a budget is the maximum amount you aim to spend on the project.

How can I use past project data to price my next construction job?

Review past jobs that were similar in size and scope to determine usage of materials, equipment, and unforeseen requirements for your next job. Additionally, look at data from your employee scheduling app to predict how many workers, hours, and shifts were required to complete the job.

What is premium versus economy pricing in construction?

Premium pricing is setting higher prices and needing fewer sales to be profitable. It’s suitable for high-quality or exclusive jobs. Economy pricing refers to setting low prices for clients with lower budgets. But, you’ll require more construction jobs to turn a profit and remain financially stable.