Tracking the latest construction trends can help you stay ahead of the curve. Learn about 9 construction trends to adopt in 2024.

Table of contents

Over the last few years, inflation, labor shortages, and supply chain problems have caused many construction companies to sink. Only those who adapted to construction market changes and emerging trends stayed afloat.

2024 will continue to be a challenging year. But knowing what’s in store can help you get ahead and overcome these challenges.

Here are 9 construction industry trends to look out for in 20204

Key Takeaways

- Non-residential projects are continuing to grow, and material costs are expected to start stabilizing.

- More companies are incorporating tech, AI, and green building practices in their construction projects.

- Finally, the use of construction management software is on the rise—with many firms using it to simplify operations, improve communications, and manage their teams.

9 Construction Industry Trends To Look Out for in 2024

Non-residential construction projects outpace the residential sector

The United States construction industry has recently faced tough times. In addition to rising labor and material costs, the Federal Reserve System (aka the Fed) heavily increased interest rates in 2023, making it very expensive to borrow money. This means construction firms have had to pay for surging costs from their own pockets, potentially putting many out of business.

While the Fed is expected to lower interest rates in 2024, recent data suggests this hasn’t happened so far. With rates still lingering between 5.25 and 5.5%, construction isn’t out of the weeds yet.

But it isn’t all bad news for 2024. The non-residential sector, in particular, is positioned to continue growing as it did last year. A large part of this is because the government is funding manufacturing construction.

Here’s what’s happening:

- The Infrastructure Investment and Jobs Act (IIJA) is leading to more funding for roads, bridges, water, airports, public transportation, and more. The IIJA aims to boost the nation’s infrastructure and improve productivity.

- The Inflation Reduction Act (IRA) offers financial incentives and tax benefits for commercial reconstruction, renewable energy plants, and energy-efficient building projects. The goal is to reduce carbon emissions and promote sustainable practices, leading to higher spending on commercial projects.

- Finally, the CHIPS (Creating Helpful Incentives to Produce Semiconductors for America) Act has increased funding for high-tech sectors, such as semiconductor manufacturing projects.

On the flip side, the residential sector continues to struggle in 2024. The rise in mortgage rates, property prices, and cost of living makes it harder for consumers to afford housing. A decrease in housing demand is stalling progress in residential construction projects.

In fact, a recent Bloomberg report showed that both multi-family and single-family home construction plummeted at the start of the year. Further, there’s been a drop in building permits—which typically indicate future construction.

But there’s light at the end of the tunnel. The Bloomberg report points to falling mortgage rates and a slow increase in demand for housing construction through the year.

What next?

Until things fully stabilize, the best way forward is to prepare for market uncertainty, financing challenges, and project delays—regardless of your sector. Additionally, try sustaining operations by working through the backlog of projects from last year.

Also, consider pursuing government-funded projects with a manufacturing or sustainability focus to keep things moving.

Lastly, buying or merging with other construction companies can be a good option. Typically, this is a reliable way to grow and run your construction business with lower risk in uncertain times.

Material costs start stabilizing—for the most part

The years following the COVID-19 pandemic have seen high inflation and steep rises in material costs across the board. Associated Builders and Contractors found that construction input prices increased by over 37% between 2020 and 2023.

However, Gordian—a leading provider of construction data—thinks things are looking up as the new year unfolds. Gordian’s data suggests that while specific product types may still face challenges, overall prices have cooled in the last six months and will continue to stabilize in 2024.

Here’s a closer look at predicted price movements for some widely-used construction materials.

What’s falling?

Diesel

Diesel fuel—used to power heavy machinery and equipment such as bulldozers, cranes, excavators, and generators—has fallen in price since last year.

Aluminum

The demand and cost of aluminum jumped 7.7% in 2021 and another 5.3% in 2022. However, a recent report by Fastmarkets believes that prices will gradually stabilize in the later months of this year owing to a more favorable economic climate.

Scraps

Construction companies use scraps to produce new building materials, such as steel for structural supports and recycled concrete. Recent data suggests that scrap prices will cool in 2024 but rise in 2025.

Drywall

Despite high prices over the last few years, the price of drywall consistently declined toward the end of 2023 and the beginning of 2024. Overall, costs are down by 11% since their peak in early 2023.

Lumber and softwood lumber

Lumber prices have decreased in the last few months, with January seeing a 1.82% drop. Prices have fallen nearly 9% year over year, too.

However, some reports suggest that lumber prices might slowly increase through 2024 as the markets balance, so it’s best to stay prepared.

What’s surging?

Steel

Prices for structural steel, conduit, and copper wire skyrocketed between 2020 and 2022 but showed signs of cooling in 2023. While they remained flat to slightly up at the start of this year, the market is expected to see a bump through 2024.

Concrete products

Prices for building materials such as ready-mix concrete were slightly up in January 2024 compared to the end of last year. They’ve also seen a yearly increase of about 7% and are expected to continue increasing.

Construction machinery and equipment

Construction machinery and equipment costs increased by about 12% between 2022 and 2023, and this trend is expected to continue into 2024. Some of this seems to be driven by long lead times—for example, for transformers and circuit breaks.

What about living or new materials?

“Living materials” have biological components that enable them to change or self-repair. For example, biocement has bacteria that heal cracks in concrete.

“New materials” are innovative or advanced materials such as 3D graphene, transparent aluminum, and invisible solar cells.

It’s difficult to predict how prices for these relatively new materials will fluctuate in 2024. Some data suggests that they could be expensive, but they’ll provide more savings in the long term.

Technology and AI takes center stage

Construction companies are embracing technology and artificial intelligence (AI) to improve efficiency, accuracy, and safety on construction sites.

These technologies are driving the construction industry toward a more digital and automated future.

BIM and AR

Building Information Modeling (BIM) creates a digital model of a building before it’s built, showing everything from pipes to electrical systems. Over 70% of construction companies have adopted BIM to plan better, save money, and finish projects faster. In fact, a recent study showed that BIM helped reduce costs and construction time by over 50%.

Meanwhile, augmented reality (AR) lets builders use specialized tablets or glasses to see how buildings will look on completion. While high costs for headsets and smart glasses might deter adoption in the short term, it’s expected to gradually increase over the next few years.

We discussed this with Samantha Odo, Real Estate Sales Representative & Montreal Division Manager at Precondo.

“The integration of advanced technologies like Building Information Modeling (BIM) and augmented reality (AR) is poised to become a norm in the construction landscape. Companies need to get tech-savvy and incorporate these tools into their workflows,” Odo suggested.

Generative AI

Generative AI uses technology to create new content, including text, code, images, videos, etc. Research shows that over 90% of construction firms either use or intend to use generative AI in their projects.

Jon Morgan, CEO of Venture Smarter, predicts, “With advancements in artificial intelligence and machine learning, companies will increasingly rely on automation to streamline processes, improve efficiency, and enhance decision-making. From automating routine tasks to optimizing complex operations, AI will revolutionize how businesses operate.”

You can explore using generative AI in the following ways:

- Produce designs based on material costs, spatial needs, budgets, and environmental factors.

- Create efficient project plans and quality control plans.

- Predict potential issues in the construction process and suggest corrective actions.

- Analyze historical data and requirements to recommend material usage, reduce waste, and lower costs.

- Predict when and where maintenance and repairs will be needed.

3D printing

This technology uses digital models to create or “print” building parts such as walls and frames with materials such as concrete, plastic, fiber, and sand. Reports suggest that 3D printing is growing rapidly and will surge in popularity throughout the decade.

Using 3D printers can help reduce transportation risks for building materials. Further, some companies found that it reduced construction timelines by up to three times and generated 99% less waste. Plus, it’s a great alternative for skilled labor that’s already hard to find in this market.

Drones

The use of drones is one of the fastest-growing construction trends. These flying cameras and sensors are used to survey land, inspect buildings, and monitor work progress. One report showed a 239% year-over-year rise in drone use.

Drones can help you map large areas quickly and use real-time data to make decisions. They can also reduce injuries by performing dangerous tasks like climbing scaffolds to inspect structures. Thanks to this technology, safety standards have improved by 55%.

🧠Did You Know?

Construction workers might need a license to operate drones. With Connecteam’s staff documents feature, you can store all your workers’ licenses and certifications. You can also set expiry dates to ensure they’re renewed on time.

Robotics and automation

Robots help automate manual and time-consuming tasks such as laying bricks or tying rebar. A recent survey found that over 50% of construction firms use robots, and over 80% are considering using them over the next decade.

💡Pro Tip:

You can use Connecteam’s company knowledge base to store, update, and share detailed guides about how your staff can safely operate robots and other machines.

Modular, pre-fabricated, and off-site construction on the rise

Today’s cost-cutting environment has put business owners and contractors under pressure to streamline processes and reduce spending.

As Samantha Odo from Precondo explained to us, “This shift necessitates a mindset [change] from traditional construction methods to embracing the modular revolution. It’s about breaking down the process into smaller, more manageable chunks and eventually building a more efficient and cost-effective future.”

Modular construction involves creating entire building sections — like kitchens, hospital rooms, office spaces, and more — offsite first, then transporting and assembling them on-site.

McKinsey expects the modular construction market to reach $130 billion by 2030.

Similar to modular construction, prefabricated construction involves building or assembling smaller components — such as wall panels, roofs, and floor systems — in a controlled factory setting.

These methods can shorten project timelines, reduce waste, and cut overall costs. Research shows that 9 in 10 construction companies find prefabrication and modular construction methods more beneficial than traditional construction.

🧠 Did You Know?

Connecteam’s online team chat allows workers to communicate from anywhere in real-time. Workers creating modular parts in factories can connect with those on job sites instantly through text, videos, images, and audio files.

Sustainable construction and green building command attention

Growing environmental concerns, regulatory pressures, and market demands have led to companies adopting sustainable construction practices. Green building is one of the biggest construction trends shaping this movement.

Green building refers to using technology, green materials, and sustainable design processes to lower a structure’s carbon footprint and greenhouse emissions—a large part of which can be attributed to building operations. Currently, about a third of single-family and multi-family use green building techniques in their projects.

Despite high short-term costs, green building practices can help you improve efficiency, gain goodwill from customers and investors, and save money in the long term.

These practices include:

- Using sustainable materials like recycled steel, bamboo, reclaimed wood, and other biodegradable materials.

- Installing solar panels and energy-efficient lighting to reduce electricity use.

- Setting up systems to collect rainwater and reusing it for watering plants, flushing toilets, and so on.

- Recycling construction waste and using methods that produce less waste during building.

- Creating “green roofs” with plants to improve insulation and reduce heat.

- Considering automated energy management, lighting control, and HVAC optimization systems. These are at the center of so-called “smart cities” or “smart buildings” and help reduce buildings’ carbon footprints.

As Andrew Wilson, Owner of Tulsa Concrete Contractors, rightfully said, “Embracing sustainable practices not only meets growing environmental concerns but also positions companies as leaders in responsible construction practices, meeting the demands of conscientious consumers and regulations.”

Safety innovations provide relief on job sites

The last decade has brought remarkable advancements in construction safety technologies. We expect more companies to adopt these innovations in 2024 and suggest incorporating them into your own practices.

Smart helmets

These combine the physical protection of a standard helmet or hard hat with technology like motion sensors, cameras, and display systems.

“Workers equipped with smart helmets can receive instant alerts about potential dangers, ranging from heavy machinery movements to proximity alerts, significantly reducing the risk of accidents,” Iu Ayala, Founder and CEO of Gradient Insight, explains.

Wearable technology

Throughout 2024, more companies will add wearable devices to personal protective equipment (PPE). These devices can monitor vital signs, detect falls, and alert supervisors to potential safety risks in real-time.

PPE comfort and fit

Construction workers are unlikely to use uncomfortable or poorly fitted PPEs. This exposes them to safety risks and can lead to non-compliance with Occupational Safety and Health Administration (OSHA) regulations.

As a result, we expect more companies to adjust gear for good fit and comfort, keeping workers’ correct sizes and preferences in mind.

For example, imagine respirators fitted to accommodate employees’ facial hair or air-purifying respirators that don’t need a facial seal.

💡Pro Tip:

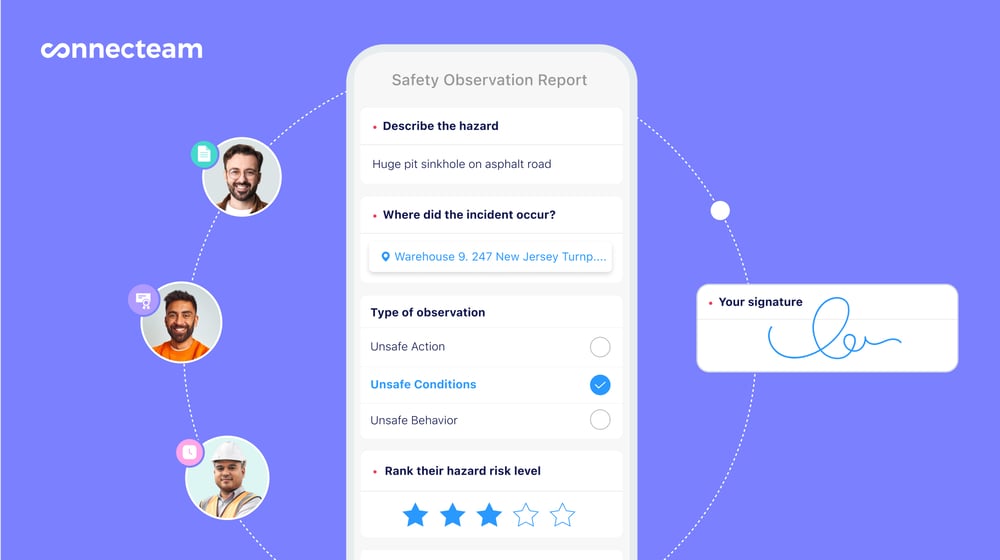

Safety innovations aren’t limited to hardware. Connecteam’s digital forms and checklists, for example, let workers send you instant reports straight from job sites. You can also search and contact your staff’s emergency contacts in seconds from the Connecteam app for extra security.

More companies use construction management software

Construction management software is becoming increasingly important as companies seek to manage dispersed projects, cut costs, and improve overall efficiency.

McKinsey reported a rise in the use of construction management software as early as 2020 and predicted it would continue growing.

Additional research showed that the global construction management software market, which was valued at $9 billion in 2021, is expected to reach $23 billion by 2031.

What is construction management software?

Construction management platforms help you manage every aspect of a construction project—from planning and scheduling to budget management and labor payments. They also allow stakeholders to communicate and access information and reports in real time.

Overall, these systems help to streamline operations, save time, and reduce mistakes in construction projects.

The best software is an all-in-one solution that includes:

- Time and location tracking

- Integrated payroll

- Job scheduling

- Shift and task management

- Real-time communications

- Built-in training

- Document management

- Reporting and analytics

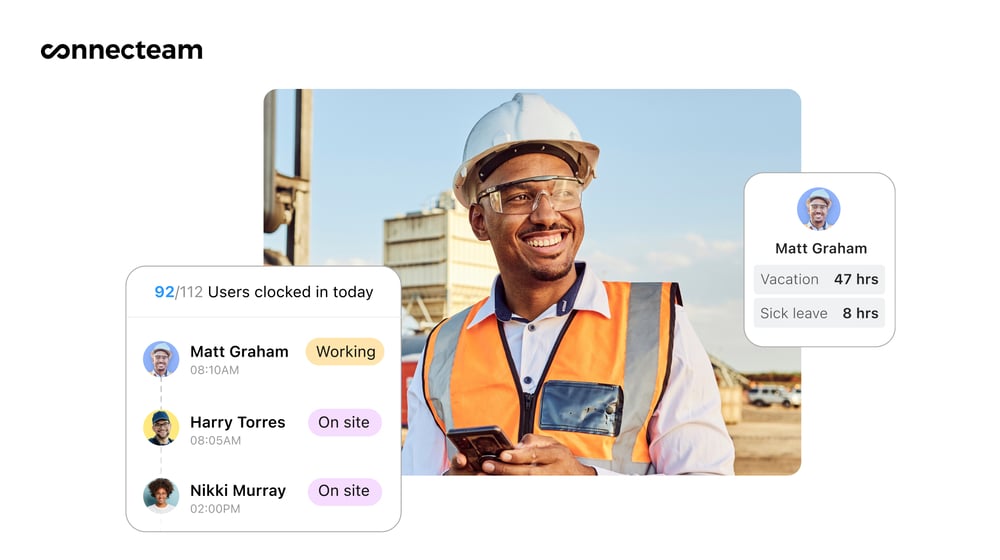

🧠Did You Know?

Connecteam’s employee time clock tracker captures workers’ hours down to the second. It also shows you their live locations so you can make sure everyone is where they should be. Plus, Connecteam’s timesheets integrate with payroll tools, leading to easy and accurate staff payments.

How to choose the right construction management software

Look for a platform that’s easy to use, suits your budget, and offers a complete set of management tools. For instance, choose software that offers payroll integration and time tracking and scheduling so you can handle everything from a single construction management app.

Further, make sure you pick a scalable platform that can help you manage your needs as you grow. Finally, check which platforms offer additional features, customization options, and good customer support so you can get your money’s worth.

📚This Might Interest You:

Read our full list of free construction company software to explore your options before committing.

Companies change HR tactics to address labor shortages

Tight labor markets have made it difficult for construction companies to hire and retain good workers. Research showed that 91% of construction contractors have recently struggled to fill open positions. This is because there’s a higher demand than supply for skilled workers.

Rafi Friedman, President of Coastal Luxury Outdoors, opened up to Connecteam about this.

“We just can’t get enough skilled workers at reasonable prices,” he said. “Specialists like concrete pourers, arborists, and pool techs are increasingly hard to find, and the ones we have been using are aging out of the profession.”

Here’s what companies are doing to recruit and retain construction workers.

Internal training

More companies are training, upskilling, and reskilling their workers to fill open roles. This is an effective way to bridge skills gaps, meet business demands, and save on costly new hires.

“It’s getting to the point where offering some of our less-skilled workers free training with us could be more affordable than paying for the increasingly rare established specialists,” Friedman said.

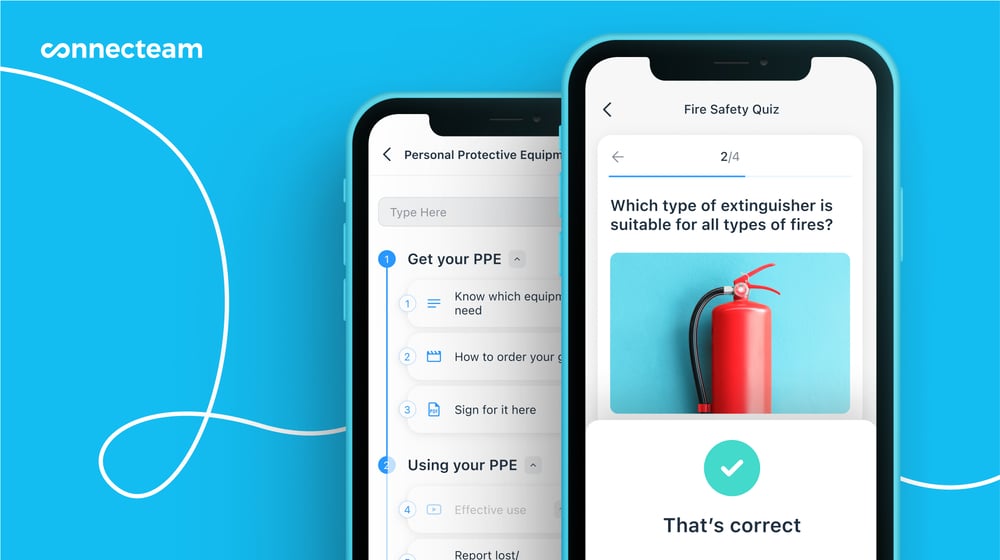

💡Pro Tip:

The best construction training platforms come with built-in training tools. For example, Connnecteam lets you create custom training courses and deliver them straight to workers’ mobile devices. You can format courses using text, videos, images, and audio and even add quizzes to make learning fun and engaging.

Offering better salary and benefits

Better pay and benefits packages can give you an edge over the competition to secure skilled construction workers. But not all companies can afford this. Those working with a tighter budget can consider offering incentives such as mental health days, flexible working arrangements, and so on.

🧠Did You Know?

With Connecteam, you can set specific rest breaks and meal times as part of workers’ schedules. This way, you comply with labor laws and give workers the downtime they need.

Widening talent pools

Michael Page, a global recruitment firm, reported that less than 10% of construction professionals are women. Amid a talent shortage, more companies are now focusing on hiring diverse talent, including gig workers, women, minorities, and military veterans.

While diversity helps companies access more candidates, Michael Page also found that it improves business outcomes by increasing creativity in the workplace.

Consider widening your talent pools by opting for inclusive language on job descriptions, connecting with minority-focused networks, and sponsoring events such as “women in construction.”

💡Pro Tip:

Ensuring your construction worker job description is free from biased or discriminatory language can help you attract diverse talent. For instance, avoid saying, “We’re looking for a strong worker to lift heavy objects,” as the word “strong” is often associated with only one gender. Instead, simply say you’re “looking for someone who can lift heavy objects.” We also collected the most common construction jobs and their expected compensation and skills for you.

Alliance, ECI, and incentive contracts replace traditional lump-sum models

In light of continuing market uncertainties, high costs, and labor shortages, many construction companies are changing how they work with contractors. Traditional agreements involved a defined scope of work and lump-sum payment made to contractors. But in 2024, you can expect to see more of the following types of contracts.

Alliance contracts

Denys Schwartz, an independent consultant in the commercial and contract management space, shared with us, “I noted that owners are looking to work alongside contractors by implementing collaborative contracting models, such as alliance contracts.”

In these contracts, business owners and contractors partner on projects, sharing cost overruns, responsibilities, and even rewards. It not only helps to spread risk but also encourages collaboration and leads to better project outcomes.

Early contractor involvement (ECI)

Schwartz also discussed early contractor involvement (ECI), which “combines the expertise of owners, designers, and contractors to ensure project success.”

In this contract, contractors are involved early in the project—for instance, during the design phase. The contractor’s practical and logistical insights enhance the project’s design and lead to more efficient and cost-effective construction processes.

Incentive contracts

Finally, with incentive contracts, companies motivate contractors to meet or exceed project objectives by offering financial incentives. These could be linked to surpassing performance targets, staying below budget, or completing the project ahead of schedule.

FAQs

What is the fastest-growing construction sector?

Several construction sectors are expected to grow in the coming years. Renewable energy is poised to be one of the fastest-growing sectors. This sector involves projects like solar and wind farms and focuses on using clean energy.

What is the most profitable construction niche?

Luxury residential and commercial real estate developments often stand out because they offer high returns. Additionally, green building and retrofitting are gaining popularity as clients prioritize sustainability. Finally, specialized plumbing, electrical, and HVAC services are also among the most profitable construction niches.

📚This Might Interest You:

Read our guide to 35 construction business ideas to identify opportunities in the construction space you might want to jump on.

How can I start a construction business?

To start a construction business, first, ensure you understand the industry. Then, pick the type of business you want to run, create a clear business plan, and secure funding. Get your licenses and insurance, then buy the tools and equipment you need. Lastly, hire skilled construction workers, market your business, and launch.

📚This Might Interest You:

Can’t think of a name for your new business? Here are 350 construction business names to help inspire you.

Conclusion

Construction firms have seen inflation, labor shortages, and many other challenges over the last few years. While things seem to be stabilizing in 2024, keeping up with the latest trends can help you improve efficiency, lower costs, and deal with lingering uncertainty.

In 2024, non-residential projects or green building are among the fastest-growing sectors — and can help you secure some government funding. Additionally, modular methods, AI and drone technologies, and safety innovations are trends that help streamline operations, cut costs, increase productivity, and improve workplace safety.

Finally, a big trend is to use an all-in-one construction management software like Connecteam. These platforms help you simplify processes, reduce errors, and retain your best workers — even in uncertain times.

Get started with Connecteam for free today.