Creating a construction quality control plan (CQCP) is crucial for maintaining project standards in construction. A well-crafted CQCP ensures quality, reduces risks and costs, and enhances market reputation.

Key Takeaways

- A construction quality control plan (CQCP) is crucial for maintaining project quality on construction sites.

- The CQCP is typically written by the contractor or the construction management team responsible for executing the project.

- A well-written CQCP helps ensure construction quality, reduces risks and unnecessary project costs, and boosts your company’s reputation.

What is a Construction Quality Control Plan?

A construction quality control plan (CQCPs) outlines a construction team’s plans to meet and exceed the quality standards expected by clients and regulators.

This document helps keep three crucial components in check: time, quality, and cost. You can think of a CQCP as a map that guides construction teams on how to achieve the best quality for every project.

You should develop the CQCP during the project planning stage and update it as needed during the building process.

Outline specific quality standards and responsibilities to ensure every phase of the project is monitored and evaluated for quality.

That way, your team can identify and fix safety issues and project errors before they become a problem.

What to Include in a Construction Quality Control Plan

Introduction and scope

The introduction and scope section should provide an overview of the plan’s purpose, objectives, project details, and client specifications. This section should serve as the foundation for the entire quality control plan so that both employees and clients have a clear understanding of the project’s goals.

Quality standards and specifications

This section of a CQCP specifies the quality requirements of the construction project. It should include references to relevant building codes, construction licenses, industry standards, and client specifications.

Roles and responsibilities

Outline your team’s organizational structure and list who has what responsibilities on the job site. You should list each person involved in quality control, including the quality control manager, project manager, inspectors, and subcontractors.

Training and competency

In the next section, you should focus on what’s required for those involved in quality control. Examples include training programs, certifications, and qualifications they must have to be involved in the process.

Did You Know?

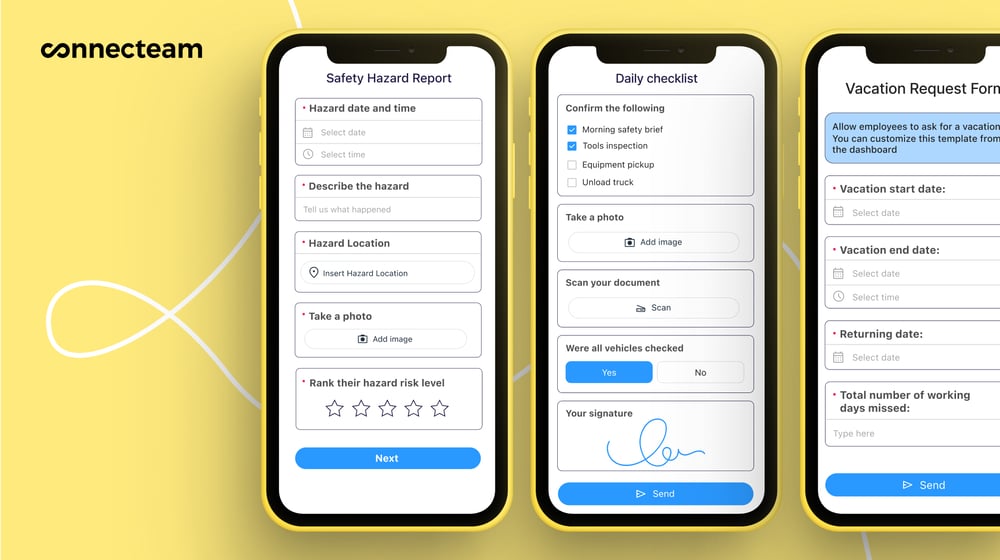

Connecteam’s employee training feature lets you create engaging and bite-sized training sessions in just a few minutes. You can then distribute the lessons to your entire team with just a click and check their knowledge with a quick quiz. The dashboard will show you exactly who took the training, who passed the test, and who needs more support.

Get started with Connecteam for free today!

Inspection and testing plans

List which inspections your team plans to conduct and who will conduct them. Be sure to include all the necessary criteria and how results will be documented.

Quality control procedures

Describe the step-by-step processes and protocols for quality control. This section should include details on how inspections and tests will be conducted, what documentation is required, and how non-conformances will be addressed.

Documentation and record-keeping

List specifically how you plan to document all quality control activities, how often, and how you’ll store the records. Effective documentation and record-keeping are crucial if you ever get audited.

Non-conformance and corrective action procedures

Provide guidelines for how you’ll address quality issues and non-conformances. You should list how you plan to identify, document, and correct errors or non-compliance with project specifications.

Communication plan

An effective communication plan is a crucial part of ensuring workplace safety and should be included in your CQCP. Define the channels, frequency, and methods of communication so stakeholders know how your team will communicate in the case of a quality control issue.

Quality control tools and equipment

List all tools, equipment, and technology that you’ll use to maintain quality control. This should include details about inspection tools, testing equipment, software, and other resources necessary for carrying out inspections and tests.

CQCP Example

To give you an idea of how each section of a CQCP should be formatted, let’s use the Quality Standards and Specifications section as an example.

Keep in mind that this example is tailored for a generic construction project, so specific details would need to be adjusted based on your actual project requirements, materials, and local regulations:

>> Download our Construction Quality Control Checklist and use it for your business <<

Quality Standards and Specifications

Objective: Ensure all construction activities and outcomes meet or exceed the defined quality standards and specifications, aligning with client requirements, industry best practices, and regulatory compliance.

1. Materials Quality Standards:

- Concrete: Must comply with ASTM C33 for coarse aggregate and ASTM C150 for Portland cement. Concrete mix shall achieve a minimum compressive strength of 4,000 psi after 28 days.

- Steel: Structural steel components shall adhere to ASTM A36 for carbon structural steel, with all welding performed according to AWS D1.1 standards.

- Bricks: Bricks used in construction must meet the specifications of ASTM C216 for facing brick and have a minimum compressive strength as per project specifications.

2. Workmanship Quality Specifications:

- Carpentry: All carpentry work shall be performed in accordance with the Architectural Woodwork Standards (AWS) and as per the detailed drawings and specifications provided by the architect.

- Electrical Installations: All electrical installations shall comply with the National Electrical Code (NEC) for safety and efficiency, ensuring all wirings, fixtures, and installations are performed by licensed electricians.

- Plumbing: Plumbing installations shall adhere to the International Plumbing Code (IPC), with all materials and workmanship ensuring leak-proof and durable water and sewage systems.

3. Safety and Environmental Standards:

- All construction practices must follow OSHA guidelines for construction safety, including but not limited to, personal protective equipment (PPE), fall protection, and hazard communication.

- Environmental compliance must align with EPA regulations, focusing on waste management, air quality control, and water pollution prevention during construction.

4. Quality Control Testing:

- Concrete Testing: Slump tests and compression tests shall be conducted as per ASTM C31 and ASTM C39 respectively to ensure the quality and strength of the concrete used.

- Soil Testing: Prior to foundation work, soil tests for bearing capacity must be conducted following ASTM D1143/D1143M standards.

- Structural Integrity: Non-destructive testing (NDT) methods, such as ultrasonic testing (UT) and magnetic particle inspection (MPI), will be employed to verify the structural integrity of welding joints and steel frameworks.

5. Final Inspection and Compliance:

- A final inspection checklist will be utilized to ensure all aspects of the construction meet the outlined quality standards and specifications.

Any deviations from the standards will be documented, and corrective actions will be taken immediately to rectify the non-compliance.

6 Key Benefits of a Construction Quality Control Plan

Reduces Rework and Saves Money:

A construction quality control plan acts as a preventative shield against costly rework.

By outlining clear inspection procedures and expectations throughout the project, issues are identified early on before they snowball into major problems requiring demolition and reconstruction.

Industry studies suggest that construction rework can consume up to 6% of project budgets, not to mention causing delays and impacting productivity.

A quality control plan helps nip these issues in the bud, saving significant time and money.

Enhances Project Schedule:

Imagine a construction project where everyone involved – from subcontractors to inspectors – is crystal clear on the specific quality standards and inspection procedures required for each phase.

This eliminates confusion and wasted time spent clarifying expectations. A well-defined construction quality control plan provides this clarity, ensuring a smoother workflow and adherence to the project schedule.

Delays caused by misunderstandings or unmet quality requirements are significantly reduced.

Improved Risk Management:

Construction projects are inherently risky endeavors, with unforeseen challenges popping up throughout the process.

A quality control plan doesn’t just focus on what should be done; it also anticipates potential problems and outlines procedures to mitigate them.

For example, the plan might identify the potential risk of improper concrete curing during cold weather and establish protocols for adding accelerators or using heated blankets to ensure the concrete sets correctly.

By proactively addressing these risks, the plan helps prevent problems before they escalate into major issues that could derail the project.

Better Communication and Collaboration:

A strong construction quality control plan fosters open communication between all stakeholders involved in the project.

This includes contractors, subcontractors, inspectors, and the owner.

The plan establishes a common ground for quality expectations, ensuring everyone is working towards the same goal.

Regular meetings and clear documentation outlined in the plan facilitate this communication, minimizing misunderstandings and fostering a collaborative environment.

Stronger Project Documentation:

A well-developed construction quality control plan creates a paper trail of the entire construction process.

This documentation includes records of inspections, tests conducted, and any corrective actions taken to address identified issues.

These detailed records serve several purposes.

They provide valuable historical references for future maintenance or renovations. They demonstrate to the owner that the project adhered to the agreed-upon quality standards.

And importantly, they can be used to settle any disputes that might arise regarding the quality of construction.

Protects Your Reputation:

In the competitive construction industry, a reputation for delivering high-quality projects is invaluable.

A construction quality control plan helps ensure consistent quality throughout the entire building process. This minimizes the chance of construction defects that could lead to costly repairs, finger-pointing, and, ultimately, damage your company’s reputation.

By consistently delivering a quality product, you build trust with clients and position yourself for future projects.

Did You Know?

While the Occupational Safety and Health Administration (OSHA) doesn’t oversee construction quality directly, it does regulate worker health and safety, which can indirectly affect project quality.

These resources can help you better understand OSHA standards to ensure you remain compliant:

- OSHA Construction Standards

- OSHA Inspection Fact Sheet

- OSHA Penalties

- Compliance Assistance Specialists (CAS)

FAQ

Who is responsible for drafting the CQCP?

The CQCP is typically written by the contractor or the construction management team responsible for executing the project.

Who oversees quality control on construction sites?

Multiple parties work together to ensure that construction processes meet the specified standards and requirements. Here’s a breakdown of the main parties responsible for overseeing quality control on a construction site:

- Construction managers: They’re responsible for the overall management of the construction project, including quality control. Construction managers coordinate between different stakeholders, manage timelines, and ensure that the work meets the required standards.

- Project owners or developers: The owners or developers of a project have a vested interest in ensuring that construction is of high quality. They may hire independent quality assurance teams or use internal resources to oversee the quality of work.

- Architects and engineers: These professionals design the project and specify materials and standards. They’re responsible for ensuring that construction adheres to project plans and specifications and often conduct site visits and inspections to monitor compliance.

- Quality control inspectors or engineers: These specialists’ primary job is to inspect and report on construction quality. They perform regular inspections and tests related to materials, workmanship, and safety to ensure compliance with building codes, standards, and project specifications.

- Contractors and subcontractors: These guys ensure that all work aligns with the detailed plans and quality standards set for the project. To manage and oversee this, contractors typically implement their own set of quality control measures.

- Government building inspectors: Local government or regulatory bodies often have building inspectors who visit construction sites to ensure compliance with building codes, safety standards, and other regulatory requirements. These inspections are mandatory and can result in fines or work stoppages if they find non-compliance.

What is OSHA’s role in construction quality and safety?

While OSHA doesn’t focus directly on construction quality, it does oversee worker health and safety.

OSHA’s role impacts construction sites by:

- Setting safety standards: OSHA establishes and enforces safety and health regulations for construction sites to protect workers from potentially hazardous conditions. These regulations cover a wide range of potential hazards, including fall protection, scaffold safety, electrical safety, and the handling of hazardous materials.

- Inspections and enforcement: OSHA conducts on-site inspections to ensure compliance with federal safety and health regulations. If OSHA detects violations, it can issue citations and fines. Inspections can be triggered by workplace accidents, complaints, or randomly selected sites as part of OSHA’s enforcement program.