Use our BRC audit checklist template as a starting point to customize yours to fit your business.

BRC Audit Checklist

Make work flow with Connecteam’s digital forms & checklists

- Easily create digital forms and checklists for any task your team needs to complete on the job

- Boost accountability by having employees add a signature, image, or location stamp

- Save time by choosing from a variety of ready-made templates

- Instantly receive your team’s submissions and share reports within your organization

- Use AI to convert PDFs, Excel files, or images into digital forms in seconds—no manual work needed

BRC Audit Checklist

Achieving BRC certification demonstrates your commitment to food safety excellence.

This comprehensive checklist guides you through the key clauses of the BRC Global Standard for Food Safety, helping you prepare for and confidently approach your next audit.

Remember, proactive assessment and continuous improvement are crucial to exceeding expectations and solidifying your position as a leader in food safety.

Instructions:

- Tailor the checklist to your specific operation and product categories.

- Assign relevant personnel to different sections based on their expertise.

- Utilize “Yes/No” answers and additional comments for a detailed evaluation.

- Review and update the checklist regularly to reflect changes in regulations and best practices.

BRC Audit Checklist

Clause 1: Senior Management Commitment

| Statement | Yes/No | Comments |

| Does senior management demonstrate commitment to food safety through active participation and investment? | ||

| Is a documented food safety policy in place, aligned with the BRC Standard? | ||

| Are measurable food safety objectives and targets established and monitored? |

Clause 2: The Food Safety Plan: HACCP

| Statement | Yes/No | Comments |

| Is a comprehensive HACCP plan implemented, covering all stages of production and food chain? | ||

| Are identified hazards assessed for severity and likelihood of occurrence? | ||

| Are effective Critical Control Points (CCPs) established for each hazard? | ||

| Are critical limits clearly defined and monitored for each CCP? | ||

| Are corrective actions documented and readily implemented when deviations occur? |

Clause 3: Food Safety and Quality Management System

| Statement | Yes/No | Comments |

| Is a documented food safety management system in place, covering all relevant processes? | ||

| Are documented procedures implemented for risk assessments, product traceability, and incident management? | ||

| Are internal audits conducted regularly to assess system effectiveness and identify improvement opportunities? |

Clause 4: Site Standards

| Statement | Yes/No | Comments |

| Is the facility clean, well-maintained, and designed for hygienic food production? | ||

| Are adequate pest control measures implemented to prevent contamination? | ||

| Are water supply and waste disposal systems maintained to meet required standards? |

Clause 5: Product Control

| Statement | Yes/No | Comments |

| Are raw materials sourced from approved suppliers with documented specifications? | ||

| Are product specifications established and regularly reviewed for accuracy? | ||

| Are effective allergen control measures implemented to prevent cross-contamination? | ||

| Are finished products stored and labelled in accordance with regulations and best practices? |

Clause 6: Process Control

| Statement | Yes/No | Comments |

| Are documented procedures in place for all production and handling processes? | ||

| Are process parameters defined and monitored to ensure product safety and quality? | ||

| Are critical equipment calibrated and maintained at optimal performance levels? | ||

| Are personnel trained and competent in their assigned tasks and hygiene practices? |

Clause 7: Personnel

| Statement | Yes/No | Comments |

| Are personnel trained on food safety principles, HACCP, and relevant procedures? | ||

| Is hygiene training conducted regularly, emphasizing proper handwashing and sanitation practices? | ||

| Do personnel wear appropriate protective clothing and adhere to personal hygiene requirements? | ||

| Is a system in place for reporting food safety concerns and potential hazards? |

Clause 8: Production Risk Zones

| Statement | Yes/No | Comments |

| Are specific control measures implemented for high-risk zones such as raw materials handling and packaging? | ||

| Is the flow of materials and personnel managed to prevent cross-contamination between product types? | ||

| Is the environment within high-risk zones monitored and controlled to meet established parameters? |

Clause 9: Traded Products

| Statement | Yes/No | Comments |

| Are procedures in place for purchasing, inspecting, and storing purchased products? | ||

| Are specifications and quality control processes for purchased products documented and implemented? | ||

| Do purchased products comply with relevant food safety regulations and standards? |

Additional Observations:

- Overall impression of food safety culture and awareness within the organization.

- Effectiveness of corrective action procedures and incident management systems.

- Level of documentation and record-keeping related to food safety activities.

Choose Connecteam, the #1 Choice for Healthy & Safety Managers

Streamline your business’s daily operations and unleash unparalleled efficiency with Connecteam!

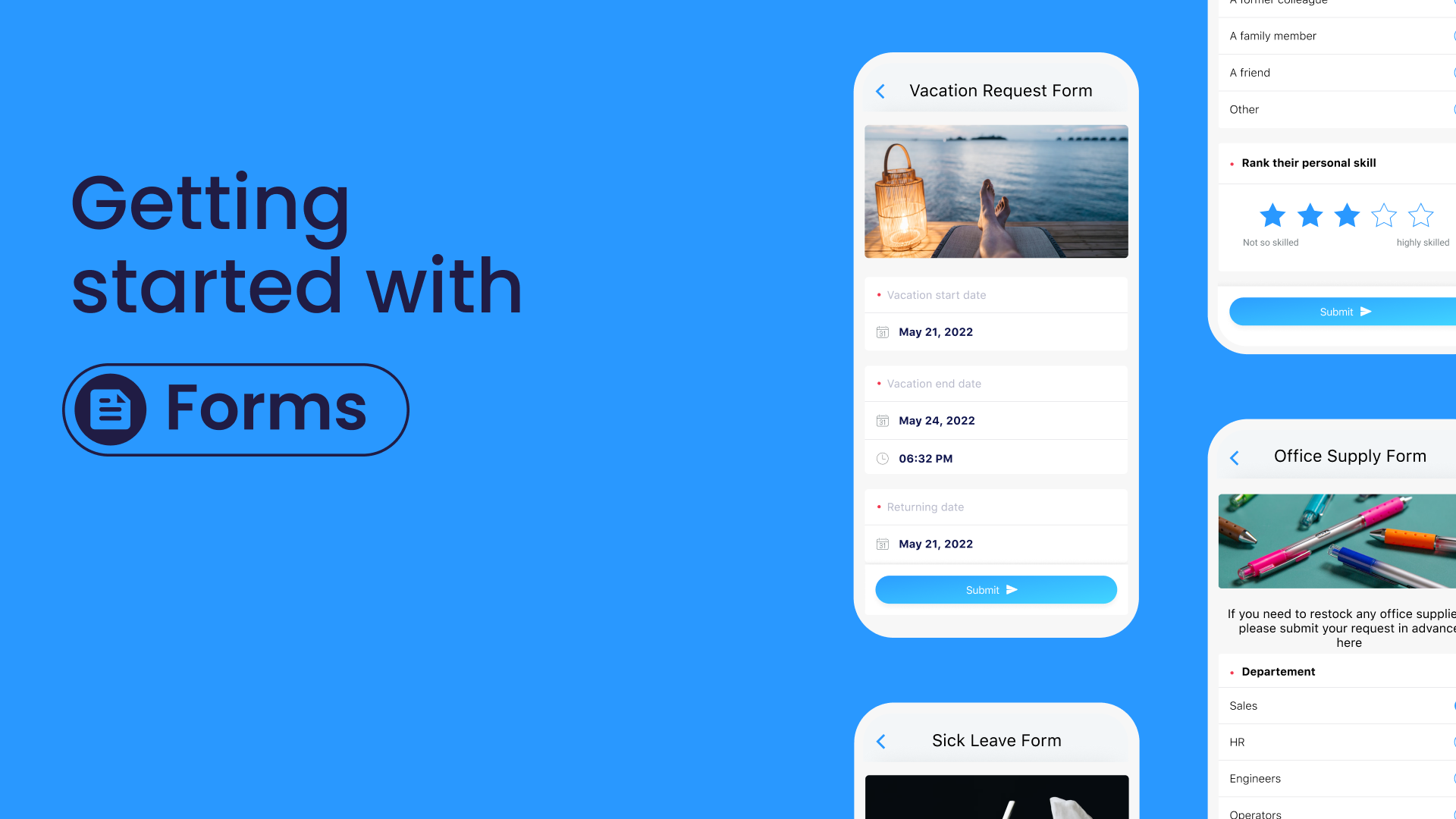

Take charge with our Forms and Checklists feature, effortlessly running your daily tasks and delivering the highest standards. But that’s just the beginning!

Easily create perfect employee schedules with our Employee Scheduler, enabling seamless staff organization and maximizing productivity. Keep a tight grip on employee work times using our Time Clock feature, making precise payroll a breeze and freeing you from mundane administrative tasks.

Stay ahead of the game with Connecteam’s built-in employee Chat, fostering real-time collaboration and empowering your team to deliver extraordinary results.

And don’t forget, continuous growth and skill development are at your fingertips with Connecteam’s comprehensive Training & Onboarding features.

Get started with Connecteam for free today and unlock the true potential of your business!

Watch the video below to see it in action:

Ready to boost your efficiency with our pre-made templates?