Quickly calculate the cost of asphalt driveway installation or replacement. Create precise estimates based on driveway size, material, labor, and additional features to streamline your project planning and budgeting.

Asphalt Driveway Cost Calculator

We’re glad you’re using our free tool! This resource is web-based and separate from the Connecteam app. Connecteam is an all-in-one solution for managing your team while this free tool is just a little bonus from us to you 🙂

How to Use the Asphalt Driveway Cost Calculator

Planning a new driveway or replacing an old one? Our calculator makes it easy to estimate costs based on key project details. Here’s how to use it:

- Enter Your Driveway Dimensions – Input the length and width of your driveway to calculate the total surface area.

- Select Asphalt Thickness – Choose between 2, 3, or 4 inches (or metric equivalents) based on durability needs.

- Choose the Project Type – Indicate whether you’re installing a new driveway or replacing an old one.

- Pick an Asphalt Type – Options include hot mix, cold mix, warm mix, and porous asphalt, each affecting the final cost.

- Select Color Options – Standard black or premium colored asphalt.

- Add Extra Features – Choose from edging, drainage installation, parking line markings, and tree root removal.

- Include Speed Bumps & Custom Additions – Enter the number of speed bumps needed and any extra custom costs.

- Apply Discounts – If applicable, enter a percentage discount for bulk pricing or special offers.

- Get Instant Cost Breakdown – The calculator automatically provides a total cost estimate and detailed expense breakdown.

This ensures you have a complete, transparent estimate before starting your asphalt driveway project.

Asphalt Driveway Cost Calculator

The Complete Guide to Asphalt Driveway Cost Estimation

Accurate cost estimation is crucial for asphalting businesses. Whether you’re bidding on a residential driveway or a large commercial project, underquoting can eat into your profits, while overquoting can drive potential clients away. This guide will walk you through everything you need to know about estimating asphalt driveway costs with precision.

Why Accurate Cost Estimation Matters

For asphalting contractors, an accurate estimate isn’t just about giving the client a number—it’s about staying competitive, maximizing profits, and ensuring smooth project execution. Here’s why cost estimation is a key part of your business success:

- Competitive Bidding – A precise estimate helps you secure jobs without underpricing yourself.

- Profit Margins – Knowing your true costs ensures you set pricing that covers materials, labor, equipment, and overhead.

- Customer Trust – Transparent estimates prevent disputes and unexpected costs that could harm your reputation.

- Efficient Project Planning – Having a clear cost breakdown helps with scheduling, material ordering, and workforce management.

Key Factors That Influence Asphalt Driveway Costs

Estimating the cost of an asphalt driveway isn’t just about material prices—it involves multiple variables, from site conditions to labor availability. Understanding these factors ensures you provide accurate estimates and maintain healthy profit margins.

1. Driveway Size

The larger the driveway, the more asphalt, labor, and time required, which directly increases the total cost. Asphalt pricing is typically calculated per square foot or square meter, meaning even small miscalculations in measurements can significantly affect your estimate.

- Residential Driveways – Usually range from 600 to 1,500 square feet.

- Commercial Driveways & Parking Lots – Can be thousands of square feet, requiring additional equipment and logistics.

- Irregularly Shaped Driveways – More complex layouts may require extra labor for grading and edging.

💡 Pro Tip: Always measure the site accurately and factor in slight overages for material calculations.

2. Asphalt Thickness

The thickness of the asphalt layer impacts durability and cost. The required thickness depends on the driveway’s expected use:

- 2 inches – Minimum for low-traffic residential driveways but may wear faster.

- 3 inches – Standard for most residential driveways, providing a balance of durability and cost.

- 4+ inches – Recommended for commercial lots, heavy vehicles, or driveways prone to high wear and tear.

Heavier-duty driveways, such as those used by trucks or heavy machinery, may require additional layers and reinforcement.

🔎 Example: A driveway meant for occasional car use will have different thickness needs than one where delivery trucks frequently park.

3. Type of Asphalt

Different asphalt types have varying costs, longevity, and performance characteristics:

- Hot Mix Asphalt (HMA) – The industry standard, providing long-lasting durability and smooth finishes. Used for most driveways and roads.

- Cold Mix Asphalt – More affordable but best suited for temporary repairs rather than full installations.

- Warm Mix Asphalt – Requires less energy to produce, making it an eco-friendlier alternative with lower emissions.

- Porous Asphalt – Designed for better water drainage but costs more due to specialized materials and installation techniques.

Choosing the right asphalt type depends on the project’s needs, budget, and climate conditions.

4. Site Preparation & Base Work

A well-prepared base is essential for a long-lasting driveway. The cost of preparation depends on the condition of the land and what work needs to be done before laying asphalt.

- Excavation – Removing old pavement, tree roots, or debris can increase costs, especially for replacements.

- Grading & Compaction – Ensures a stable, even surface that prevents cracks and water pooling.

- Base Layer Installation – A gravel or crushed stone foundation improves structural integrity and prevents premature wear.

🚧 Did You Know? Poor base preparation is the leading cause of premature asphalt failure, leading to cracks, potholes, and drainage issues.

5. Additional Features

Clients often request additional customizations that add to the overall cost:

- Edging & Bordering – Strengthens driveway edges and enhances curb appeal.

- Drainage Systems – Essential in areas with heavy rainfall to prevent erosion and cracking.

- Parking Lines & Markings – Necessary for commercial spaces or multi-vehicle driveways.

- Speed Bumps & Custom Features – Can add functionality but require additional materials and labor.

Each of these factors should be considered when preparing a detailed estimate.

6. Labor Costs

Labor expenses can vary widely based on:

- Project complexity – A straightforward residential driveway costs less to install than a commercial parking lot.

- Crew size – More workers may speed up completion but increase costs.

- Regional labor rates – Some areas have higher construction labor costs due to demand and union regulations.

Hiring a skilled team may cost more initially but reduces the risk of errors, rework, and warranty claims.

7. Equipment & Machinery

Larger projects may require specialized equipment beyond standard paving tools. Costs to consider include:

- Asphalt pavers – Essential for laying smooth, even asphalt.

- Rollers & compactors – Used for achieving proper density and preventing air pockets.

- Dump trucks – Transport asphalt from the plant to the job site.

If you own the necessary equipment, maintenance and fuel costs should be factored in. For businesses renting machinery, rental fees can significantly impact project expenses.

8. Material Costs & Supply Chain Factors

Asphalt is a petroleum-based product, meaning its price fluctuates with crude oil prices. Other cost considerations include:

- Bulk purchasing discounts – Buying materials in larger quantities may lower costs but requires proper storage.

- Transportation fees – If suppliers are far from the job site, delivery costs may increase.

- Regional price variations – Some areas have higher material costs due to demand or regulations.

📦 Pro Tip: Establish strong relationships with multiple suppliers to get the best material rates and avoid delays.

9. Project Type: New Installation vs. Replacement

- New Driveway Installations – Typically more expensive due to the need for full site preparation, base work, and asphalt layering.

- Driveway Replacements – Involves removing old asphalt, which can add labor and disposal costs, though existing base materials may sometimes be reused to save on expenses.

Knowing whether the project is a full installation or a replacement helps you refine your pricing strategy.

10. Seasonal & Regional Considerations

Asphalt work is seasonal in many regions, affecting labor availability and pricing:

- Peak Season (Spring & Summer) – Higher material and labor costs due to demand.

- Off-Season (Fall & Winter) – Fewer projects may lower prices, but cold weather can impact asphalt quality.

- Regional Climate – Cold regions require asphalt mixes that withstand freeze-thaw cycles, while hot climates may need heat-resistant formulations.

If possible, plan projects during optimal weather conditions to reduce material complications and ensure smoother installation.

How Much Does an Asphalt Driveway Cost?

Average Cost Breakdown

| Driveway Size | Estimated Cost (Standard Black Asphalt) |

|---|---|

| Small (400 sq ft) | $1,200 – $2,400 |

| Medium (800 sq ft) | $2,400 – $4,800 |

| Large (1,200 sq ft) | $3,600 – $7,200 |

| Extra-Large (2,000 sq ft) | $6,000 – $12,000 |

How to Accurately Estimate Asphalt Driveway Costs

Providing accurate cost estimates for asphalt driveway projects is essential for ensuring profitability while keeping clients informed. Here’s how to structure your estimates effectively:

Measure the Project Area

Start by determining the total area that needs paving. Use a tape measure or aerial measurement tools to calculate the length and width, then multiply them to find the total square footage. If needed, convert square footage to square meters based on project specifications.

Select Asphalt Thickness

Asphalt thickness impacts both durability and cost. Standard residential driveways typically require 2–4 inches, while commercial or high-traffic areas may need a thicker asphalt layer. Ensure that the thickness you select aligns with the expected vehicle load and local regulations.

Factor in Material Costs

Material costs can vary depending on asphalt type, supplier pricing, and delivery fees. Get updated pricing from suppliers and factor in potential fluctuations due to oil prices. Purchasing materials in bulk may reduce per-unit costs, but be mindful of storage limitations.

Estimate Labor & Equipment Costs

Labor costs depend on the size of your crew, their hourly rates, and project duration. If you own the necessary equipment, calculate fuel and maintenance expenses. If renting, factor in daily or weekly rental fees for pavers, rollers, and dump trucks. A well-planned schedule helps minimize labor inefficiencies and unnecessary rental costs.

Account for Additional Features

Many clients require extra services, which should be clearly outlined in your estimate. These may include:

- Drainage systems for water runoff management

- Edging and bordering for structural reinforcement

- Parking lot line striping for commercial projects

- Tree root removal or land preparation

- Speed bumps or other safety features

These add-ons contribute to the final cost and should be priced accordingly.

Apply Markups & Profit Margins

Your estimate should include a markup on materials, labor, and equipment costs to ensure a profitable return. Many asphalt contractors apply a 10-30% markup, but this varies based on business expenses, competitive pricing, and market conditions.

Provide a Transparent Estimate to Clients

Once you’ve compiled all cost factors, present the estimate in a clear and itemized format. Breaking down the costs into labor, materials, equipment, and additional features helps clients understand what they’re paying for and builds trust. Transparency can also reduce back-and-forth negotiations and improve conversion rates.

Best Practices for Improving Your Estimation Process

- Use a Digital Calculator – Automate calculations to reduce errors.

- Track Past Projects – Compare estimated vs. actual costs to refine future estimates.

- Stay Updated on Material Prices – Asphalt and fuel prices fluctuate frequently.

- Get Supplier Quotes Early – Lock in pricing to avoid unexpected cost increases.

- Account for Unforeseen Expenses – Always include a contingency buffer.

Manage Your Asphalting Business with Ease Using Connecteam

Running an asphalting business requires more than just accurate cost estimates—you need the right tools to manage your team, track jobs, and ensure projects stay on schedule and within budget. That’s where Connecteam comes in. Our all-in-one workforce management platform helps asphalt contractors streamline operations, improve efficiency, and boost profitability.

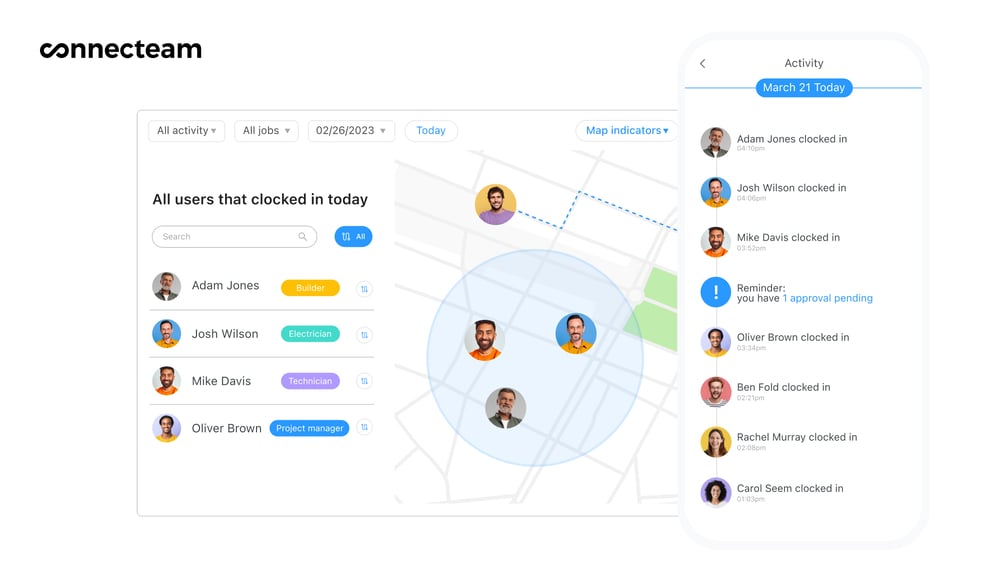

Track Labor Costs in Real-Time

Labor is one of the biggest expenses in any asphalting project. With Connecteam’s time clock, employees can clock in and out from their mobile devices, ensuring accurate payroll and job costing. The GPS-enabled time tracking feature allows you to:

- Monitor when and where employees clock in.

- Prevent time theft and buddy punching.

- Ensure workers are paid accurately for their time on-site.

Say goodbye to paper timesheets and manual hour calculations—Connecteam keeps everything organized and automated.

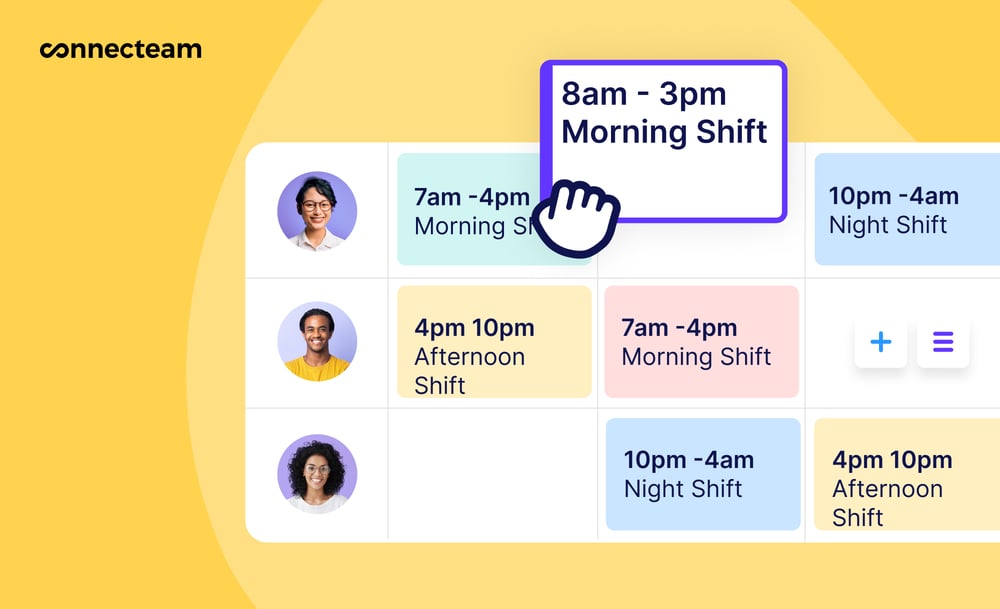

Simplify Job Scheduling & Dispatching

Coordinating multiple paving projects? Connecteam’s job scheduling tool makes it easy to assign crews to specific job sites, update schedules on the fly, and send instant notifications about weather delays, last-minute changes, or equipment needs. Features include:

- Drag-and-drop scheduling for easy shift planning.

- Job tags to categorize projects by client, location, or type.

- Mobile notifications to ensure employees know their assignments.

With real-time updates, you can reduce miscommunication and keep every project running smoothly.

Track Job Costs & Project Progress

Need insight into where your labor hours and materials are going? Connecteam helps you track:

- Time spent on each job to ensure labor costs match estimates.

- Task progress to monitor productivity and prevent delays.

- Equipment usage to optimize rental periods and reduce unnecessary expenses.

With detailed job reports, you’ll gain full visibility into your costs and profitability for every project.

Improve Team Communication On-Site & On the Go

Effective communication is crucial in construction. Connecteam’s built-in chat and updates ensure that everyone—from crew members to office staff—stays connected.

- Send important job updates and safety reminders instantly.

- Share documents, blueprints, and checklists in one central app.

- Keep all team conversations in one place instead of scattered across emails and text messages.

No more missed messages or miscommunication—your entire team will always be in the loop.

Streamline Payroll & Compliance

As a business owner, staying compliant with labor laws and payroll regulations is critical. Connecteam helps you:

- Export accurate timesheets directly to payroll software.

- Track overtime and breaks to avoid labor law violations.

- Maintain digital records for audits and compliance checks.

This means less admin work and fewer payroll disputes, so you can focus on growing your business.

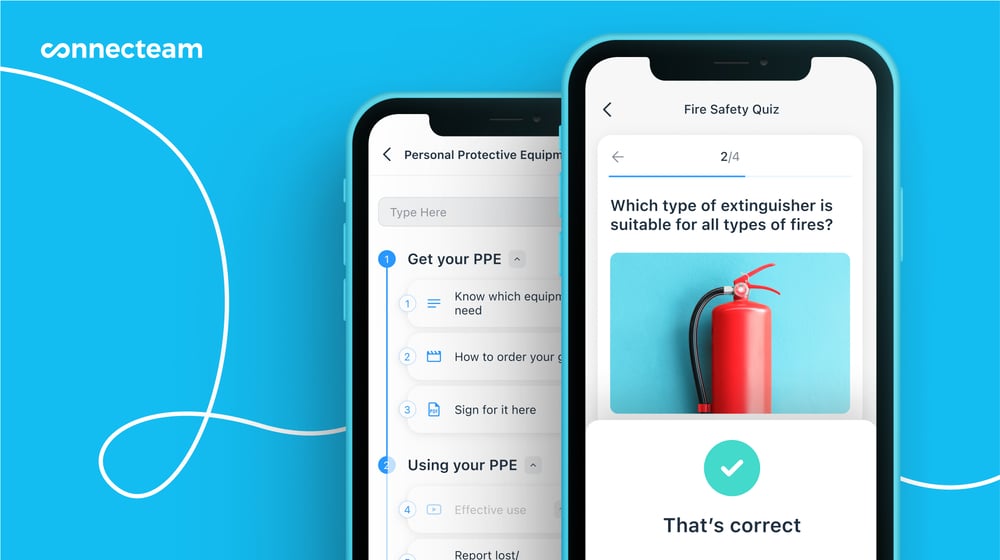

Train & Certify Your Crew in One Place

Need to onboard new workers or ensure your team is certified for specific jobs? With Connecteam’s training and onboarding tools, you can:

- Create custom training modules for safety procedures and best practices.

- Track who has completed required certifications for compliance.

- Ensure new hires get up to speed quickly without disrupting operations.

A well-trained team is a safer, more efficient team—and that means fewer costly mistakes and delays.

👉 Get started with Connecteam for free today and take your asphalt business to the next level!

FAQs

The Asphalt Driveway Cost Calculator is an online tool designed to estimate the cost of installing or replacing an asphalt driveway. It helps users calculate costs based on dimensions, material type, additional features, and custom inputs, providing a detailed breakdown of expenses.

Simply input your driveway’s length, width, thickness, and select additional options like asphalt type, color, and optional features. The calculator will automatically factor in all inputs to generate a detailed cost estimate tailored to your project.

Several factors impact the cost, including:

- Dimensions: Length, width, and thickness of the driveway.

- Asphalt Type: Hot mix, cold mix, or porous options have different pricing.

- Project Type: Installing a new driveway versus replacing an old one.

- Additional Features: Edging, drainage, parking lines, and more.

- Customization: Unique features or requirements you add to the project.

Yes! The calculator allows you to specify whether the project is for a new installation or a replacement. Costs for removal and preparation are factored into replacement projects.

Absolutely! Enter a discount percentage in the designated field, and the calculator will adjust the total cost accordingly.

You can select additional features such as edging, drainage installation, parking lines, and tree root removal. Each feature is calculated separately and added to the total cost to ensure a precise estimate.

While the calculator provides highly accurate estimates based on industry standards, actual costs may vary depending on factors like regional pricing, labor costs, and site-specific conditions. Always consult a professional for final quotes.

Yes! You can add custom inputs for unique features or services, including a description and cost, to ensure the estimate matches your specific needs.

- Hot Mix Asphalt: Ideal for most driveways, offering durability and smooth surfaces.

- Cold Mix Asphalt: Often used for quick repairs or smaller projects.

- Porous Asphalt: Environmentally friendly and allows water to drain through.

The calculator focuses on installation and replacement costs, but you can customize inputs to include estimates for maintenance services like resurfacing or repairs.