We compare the top maintenance management software solutions to help businesses streamline operations, reduce downtime, and choose the best tool for their team.

Keeping up with maintenance tasks shouldn’t feel like a constant scramble.

The right software can help you stay on top of work orders, plan preventive maintenance, and keep equipment running without the surprise breakdowns.

I looked at 6 top maintenance management tools to help you find the one that fits best, including:

Our Top Picks

-

1

Best all-in-one maintenance management software solution.

-

2

Good for digital work orders and inspections

-

3

Good for automation and asset tracking

Why trust us?

Our team of unbiased software reviewers follows strict editorial guidelines, and our methodology is clear and open to everyone.

See our complete methodology

How I Chose the Best Maintenance Management Software

So, what makes good maintenance software stand out? Here’s what I checked:

Must-have features

- Work order management: The software should make it easy to create, assign, and track maintenance tasks so nothing falls through the cracks.

- Preventive maintenance scheduling: You need to be able to schedule recurring maintenance tasks.

- Asset management: The software should let you track equipment details, including performance, repair history, and important documents.

- Mobile accessibility: Maintenance teams must be able to access the tool on the go.

I also made sure the software is:

- User-friendly so any team can jump right in without extensive training.

- Scalable to grow with your business and workload.

Finally, I checked for features that make maintenance software even better:

- Inventory management to stay on top of spare parts and avoid delays.

- Reporting tools to spot trends, track performance, and make smarter decisions.

- Integrations that connect with your other systems seamlessly.

The 6 Best Maintenance Management Software Tools

-

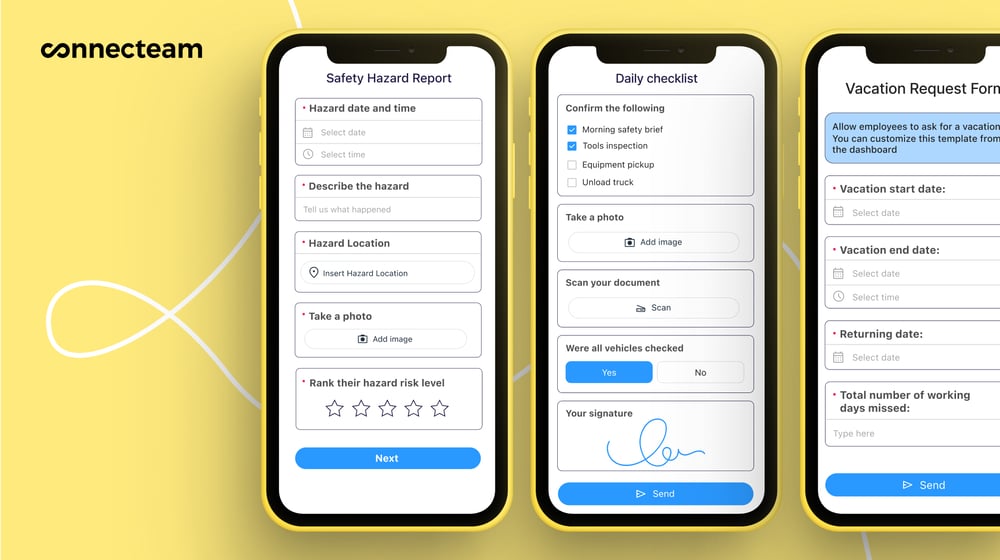

Connecteam — Best all-in-one maintenance management software solution

Connecteam is an all-in-one management tool built to simplify everyday work for maintenance crews, field techs, and facility managers. It keeps everyone connected, organized, and focused on the job instead of chasing down paperwork or missed updates.

Here’s what else Connecteam has to offer:

Why I chose Connecteam: Connecteam offers more than just maintenance tracking. I like that Connecteam is like a full tool belt in your pocket, with operations, communication, and HR tools in one app. It’s ideal for teams who need to get things done in the field, not just behind a desk.

Scheduling and time tracking

I liked how easy it was to build and manage maintenance schedules with Connecteam. It’s convenient for planning recurring tasks or filling in last-minute jobs. You can use templates, set up recurring shifts, and assign technicians to specific tasks or locations straight from the schedule. It’s especially useful for routines that need to stay on a set schedule.

Any updates you make appear in real time and teams can access schedules right from their phones. You can even send a copy of the schedule to a client, so they know what to expect.

Technicians can use the employee time clock directly from their phones, with GPS tracking if you want to verify where they’re starting or finishing a job. It’s a simple way to log hours accurately without chasing timesheets. The best part? All the logged hours are stored in digital timesheets, ready for payroll.

Task management and forms

Connecteam makes it easy to assign tasks and track progress from start to finish. You can send work orders to one person or an entire team, complete with due dates, notes, custom checklists, photos, and even location details. I liked that technicians get instant notifications on their phones and can check off subtasks and checklist items as they go. If anything runs late, both the employee and manager get notified.

If someone has a question, they can comment directly inside the task, keeping all the back-and-forth where it belongs. I thought it was a clean, simple way to stay on top of employee task tracking.

On top of that, you can replace paper-based reports with digital forms and checklists for inspections, maintenance logs, and safety checks. The reporting tools help you track what’s getting done, how fast, and where things might be getting stuck. It’s a great way to catch patterns early and make smarter calls moving forward.

Stay connected

Another thing I really appreciate about Connecteam is how it keeps all communication in one place. There’s an online team chat for quick back-and-forth, a company update feed for announcements, and a built-in company employee directory so you can easily find and reach the right person.

There’s no need to switch between apps or dig through text chains to find what you need. Whether it’s a heads-up about a task, a schedule change, or just a quick question, everything’s right there in the app. It’s a simple way to stay in sync and make sure nothing gets missed.

Integrations

Connecteam offers a great range of integrations and an API, including:

And so much more…

Connecteam has so many other features to help run a maintenance team. The team documents feature lets you store and organize things like certifications, licenses, and onboarding paperwork. You can also build onboarding and training courses that technicians can complete right from their phones. And the company knowledge base is perfect for uploading how-to guides, safety manuals, and troubleshooting steps, so your team always has the info they need, right when they need it.

0Key Features

- Job scheduling

- Task management

- Digital forms & checklists

- In-app team communication

- Real-time updates

- Time tracking

Pros

- All-in-one solution

- Mobile-first design

- Easy-to-use

- Free plan for small teams

Cons

- Needs internet or Wi-Fi access to work

Pricing

Free-for-life plan availablePremium plans start at $29/month for 30 users

14-day free trial, no credit card required

Start your free trial -

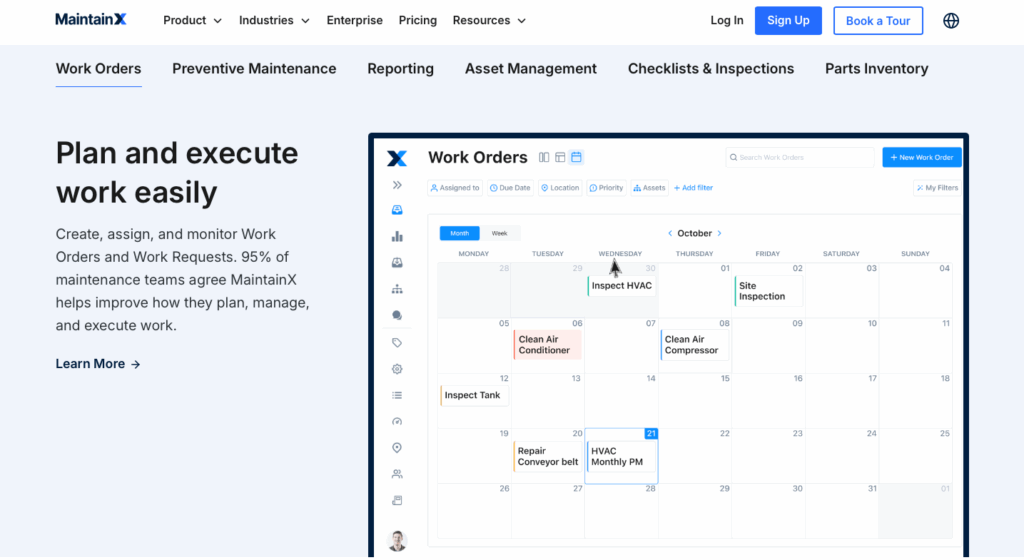

MaintainX — Good for digital work orders and inspections

Available on

- Web

- iOS

- Android

- Windows

- Mac

MaintainX is a smart, maintenance-focused platform built to keep equipment running and teams on track. It’s designed to help teams stay ahead of preventive maintenance and compliance tasks.

Why I chose MaintainX: I liked that MaintainX handles work orders, preventive maintenance, and inventory in a way that’s easy to understand. The mobile app is solid, and the interface is clean, which is great for teams that need to stay organized without a steep learning curve.

Work order management

It was pretty quick to create work orders, and I liked that you can easily add images, procedures, and checklists. It’s simple to assign tasks, set priorities, and track progress in real time.

MaintainX updates work orders in real time, which was helpful. You can also break tasks into subtasks to keep track of more complex jobs. And with automatic notifications for new assignments, updates, or overdue tasks, everyone stays in the loop without constant follow-up.

Preventive maintenance and inventory parts

MaintainX does a good job with preventive maintenance. I liked that I could set up recurring tasks based on time or meter readings, and the system auto-generates work orders so nothing gets missed. The calendar view gives you a clear snapshot of what’s coming up.

If you use IoT sensors, MaintainX can trigger work orders automatically based on equipment condition, so your team can catch issues early and stay ahead of breakdowns, which I liked a lot.

For parts inventory, it was helpful being able to track usage, set minimum stock levels, and get alerts when supplies run low. Parts can be linked directly to assets and work orders, so technicians have what they need before they start.

Where it falls short

MaintainX covers the maintenance basics really well, but there are a few trade-offs to keep in mind. I noticed that the per-user cost is higher than some other options, which can add up fast for larger teams. Some of the more advanced features, like detailed reporting and downtime analysis, are also only available on the higher-tier Enterprise plans.

I also thought scheduling could also be smoother. It’s not always easy to reorder jobs on the calendar, and it can be hard to see who’s assigned to what at a glance. That can make planning a bit tricky, especially for teams working across multiple sites or complex routes.

What users say about MaintainX

Read review here.MaintainX makes it very easy to assign, track, and complete work orders. I especially like the app – it’s fast, intuitive.

Read review here.I would have liked to have a tab dedicated strictly to documents that have been uploaded. This would have helped with minimizing the need to have organized files elsewhere.

Key Features

- Work order scheduling

- Parts inventory tracking

- Real-time updates

- Task management

Pros

- Strong mobile app

- Fast set up and easy navigation

Cons

- Higher per-user cost

- Limited scheduling

Pricing

Starts at $16/user/month Trial: Yes Free Plan: Yes

-

Limble CMMS — Good for automation and asset tracking

Available on

- Web

- iOS

- Android

- Windows

- Mac

Limble is a maintenance and asset management platform that helps teams cut downtime, stay ahead on preventive maintenance, and keep work orders organized.

Why I chose Limble CMMS: I picked Limble for its smooth user experience and strong asset management tools. It felt intuitive and easy to use. For teams that don’t want a steep learning curve, Limble is a solid option.

Work order system

I found that creating and managing work orders in Limble is pretty simple and efficient. You can include detailed procedures, checklists, and images to give your team all the context they need. The mobile app lets techs update work in real time, attach photos, and log notes from the field.

That said, Limble doesn’t have built-in communication tools like chat or updates feeds. If you need to coordinate with your team, you’ll still need to rely on an external platform, which can be a bit of an inconvenience when you’re juggling active work orders.

Asset management

Limble does a pretty good job when it comes to asset tracking. You can build out detailed asset hierarchies, track key performance metrics, and monitor downtime. I liked how easy it is to attach QR codes to equipment, so technicians can pull up asset history, documents, and repair logs on the spot. The platform also includes MTBF and MTTR reports to help spot issues and decide when repairs or replacements make the most sense.

Preventive maintenance

Preventive maintenance is one of Limble’s strengths. You can set up recurring tasks based on time, usage, or meter readings, and the system automatically generates work orders when those triggers are hit. It’s a great way to stay proactive and make sure you don’t miss anything.

The calendar-based scheduling tools are easy to work with, and the automated work order generation saves time and helps avoid missed maintenance. This is especially helpful for high-use or critical equipment that needs consistent upkeep.

Things to consider

I thought that the setup process wasn’t as fast as it could be. The platform requires more initial configuration than some of the more plug-and-play options out there. If you’re looking to dive right in, it’s probably going to take some time to get it tailored to your workflow.

Another thing to mention is that Limble doesn’t list pricing on its website, so you need to request a custom quote. That can make it harder to budget or compare options if you’re shopping around. Also, there’s no free plan, just a 30-day trial, which may be a hurdle for smaller teams or those looking for a longer-term test drive.

What users say about Limble CMMS

Limble provided a way for our company to proactively track our fleet for scheduled maintenance. It also provided a way to reference maintenance records all in one location.

The start up was very time consuming, especially around the PM schedules, since we didnt have those documented.

Key Features

- Mobile work order access

- MTBF and MTTR reporting

- Calendar/meter triggers

- Inventory tracking

Pros

- Real-time updates

- QR code asset info

Cons

- Takes time to set up

- No internal communication

Pricing

Contact vendor for price Trial: Yes — 30-day Free Plan: Yes — No

-

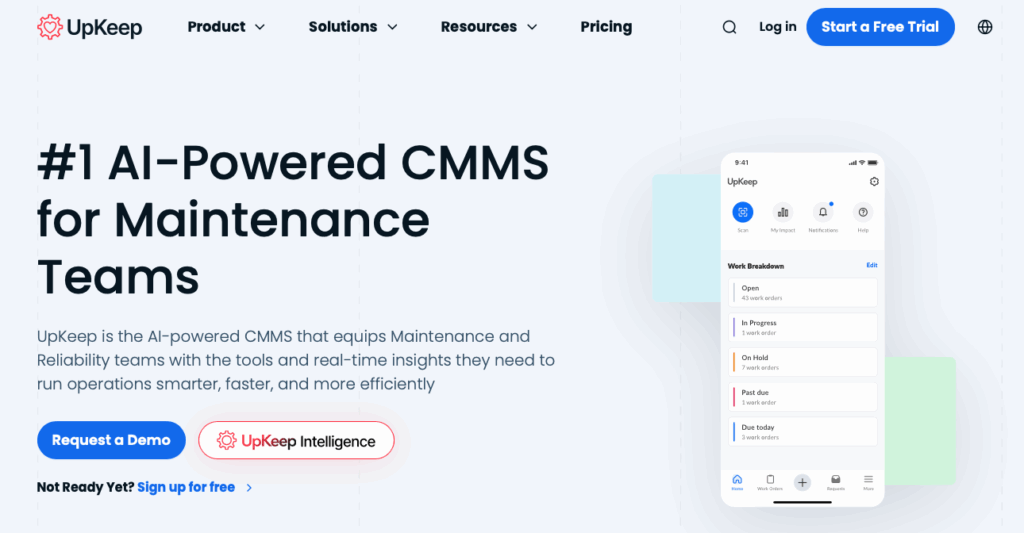

UpKeep — Good for AI insights and inventory tracking

UpKeep is a CMMS and asset management platform built with AI and IoT in mind. It’s designed to give maintenance teams tools for staying ahead of equipment failures and making data-backed decisions in real time.

Why I chose UpKeep: I liked how innovative UpKeep’s approach to predictive maintenance was. With AI-powered insights and sensor integrations, it helps you spot issues before they become problems.

AI-Powered Insights

UpKeep’s AI features are a standout. The platform analyzes your maintenance data to catch patterns, flag risks, and recommend preventive actions. I can see this kind of predictive support being really helpful.

That said, these advanced AI features are only available on higher-tier plans. If you’re not ready to pay for premium access, you won’t get the full benefit of what UpKeep can do in this area.

Work order management

Creating and managing work orders in UpKeep is straightforward. You can include instructions, checklists, and images with each task, and technicians can update everything in the field using the mobile app. It’s flexible and works well for field teams.

However, even with its clean interface, I found UpKeep has a steeper learning curve than some competitors. It might take more time (and more training) for new users to get fully comfortable, especially if your team isn’t very tech-savy.

IoT integration

UpKeep’s IoT capabilities let you connect directly to sensors that monitor things like temperature, vibration, and current. This is great for condition-based maintenance, where work orders are triggered by real-time data instead of a fixed schedule.

It’s a powerful tool if you want to run your operations more efficiently and catch issues early on. But again, this functionality is only available on premium plans, which could put it out of reach for smaller teams or businesses with tighter budgets.

What to keep in mind

UpKeep’s per-user pricing model can get expensive fast. Even at the lower end, $20 per user per month, a team of 25 could be looking at over $500 a month. For growing teams, that’s a serious investment.

Another limitation is the lack of built-in employee management features like time tracking with GPS. If you manage a field service crew, I think you would probably need a separate tool to handle time and attendance, which adds to the complexity and cost.

What users say about UpKeep

Read review here.Upkeep helps to track completion of routine tasks , assets, and projects in a timely manner It is an improvement for our organization in being proactive for maintenance items and reducing operating expenses.

Read review here.It has a learning curve and takes some time to get used to as there are many different options which can easily be messed up with one another.

Key Features

- Work order creation and tracking

- Checklists and image attachments

- AI-powered insights

- IoT sensor integration

Pros

- Clean, modern interface

- Strong predictive maintenance tools

Cons

- Some tools only available at higher tiers

- Expensive per-user pricing

Pricing

Starts at $20 per month per user Trial: Yes — 7 days Free Plan: No

-

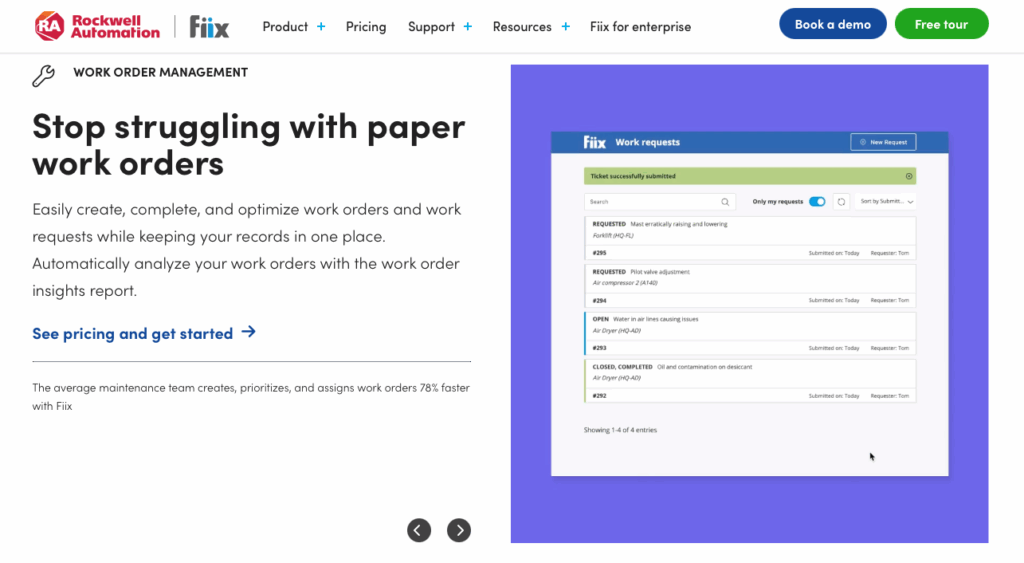

Fiix — Good for predictive maintenance and integrations

Available on

- Web

- iOS

- Android

- Windows

- Mac

Fiix is a cloud-based CMMS from Rockwell Automation, built to help companies streamline maintenance and hit their uptime goals.

Why I chose Fiix: I liked Fiix for its deep integration capabilities. It combines solid maintenance tools with enterprise-level connectivity, which is great for teams that want to move from manual tracking to smarter, automated processes.

Work orders

It was easy to create and track work orders with Fiix, complete with detailed instructions, checklists, and file attachments. Assigning tasks and following progress was also straightforward. I liked that technicians can make updates from the field on the mobile app.

However, I thought that both the desktop and mobile experiences weren’t quite as polished as some other platforms. Navigation can feel clunky, especially on the mobile app for technicians who need fast, on-the-go access to task info.

AI-powered insights

Fiix Foresight, the platform’s AI feature, helps identify trends in your maintenance data, which I thought was interesting. It can suggest changes to your preventive maintenance schedule or flag recurring issues before they get out of hand.

It’s important to note that like many advanced features in Fiix, this kind of insight comes at a price. It’s only available on higher-tier plans, which can drive up monthly costs quickly.

Integration capabilities

This is where Fiix really stands out. It connects smoothly with ERP systems, SCADA, IoT platforms, and more to reduce manual work and give you a full view of your operations. If you’re running a larger or more complex setup, this level of connectivity can be super helpful.

For smaller teams, though, all that enterprise functionality might feel like too much. The setup process is more involved, and many features are geared toward industrial use cases that smaller operations may never need. Plus, with a steep price tag starting at $45 per user per month, it might be hard to justify.

What users say about Fiix

The user interface is very clear and presents all the all necessary details in a clear overview. The analysis options are very extensive.

Fiix is the very suitable of using Web version. Application is not user friendly than other CMMS. Little bit confused at beginning.

Key Features

- Mobile app access

- ERP, SCADA, IoT integrations

- Reporting and analytics dashboards

- Work order creation and tracking

Pros

- Integrations with enterprise systems

- AI-powered insights

Cons

- More complex set up

- Clunky user interface

Pricing

Starts at $45/user/month Trial: No Free Plan: No

-

eMaint CMMS — Good for enterprise operations and compliance

Available on

- Web

- iOS

- Android

eMaint is a CMMS and EAM platform from Fluke Reliability, built for large organizations with complex maintenance needs. It connects software, hardware, and IIoT tools in one system.

Why I chose eMaint CMMS: I picked eMaint for its deep asset management features. It’s a great fit for organizations looking for predictive maintenance strategies.

Connected reliability

One of eMaint’s main strengths is how well it integrates with Fluke’s monitoring hardware and IIoT sensors. This connection gives you visibility into the health of your equipment, which can be helpful when you’re trying to shift from scheduled to condition-based maintenance.

This kind of integration is good for predictive maintenance strategies, but I also felt like it leans more heavily toward enterprise use cases. Smaller teams or companies without access to sensor networks may not get as much value from eMaint.

Interactive asset mapping

The image mapping feature in eMaint is something I liked a lot. You can upload layouts of your facility or equipment and place clickable hotspots directly on the image. Each hotspot can link to work orders, maintenance records, asset histories, or manuals. It’s a smart, visual way to navigate the system, and it helps field techs and maintenance leads find what they need faster, especially in larger or more complex facilities.

Workflow management

eMaint’s workflow tools were customizable, and I liked how I could decide how maintenance tasks are created, assigned, reviewed, and prioritized. You can build out approval chains, set custom rules for how requests move through the system, and tailor processes to match your company’s internal policies or compliance needs.

The trade-off here is complexity. The interface and feature depth make eMaint feel more like an enterprise platform. I found that setup and onboarding take more time, and the system requires training before most teams can use it efficiently. If you’re looking for a tool you can use on day one, eMaint may feel overwhelming at first.

Comes at a (high) cost

eMaint has one of the highest starting prices. Plans begin at $69 per user per month. That adds up quickly, especially for mid-sized or growing teams. A 25-person team could end up paying $1,725 a month, before you even factor in training or system configuration costs.

In addition, eMaint has minimum user requirements per plan, which forces smaller teams to pay for more licenses than they actually need. And while it excels at asset and maintenance management, it doesn’t include built-in tools for team communication, time tracking, or scheduling.

What users say about eMaint CMMS

eMaint helps us keep track of the PMs and Spare parts over 17 plants. It is great having a system that I can go into and see all of the plants and how they are always doing.

Creating reports and other tasks on the administrator side requires more coding experience than other software packages.

Key Features

- Interactive asset mapping

- Preventive maintenance scheduling

- Reporting and compliance support

- Integration with IIoT sensors

Pros

- Customizable workflows

- Good for large maintenance operations

Cons

- Minimum user requirements per plan

- Longer setup time

Pricing

Starts at $69/month Trial: Yes Free Plan: No

Compare the Best Maintenance Management Software Tools

| Topic |

Start for free

Start for free

|

|

|

|

|

|

|---|---|---|---|---|---|---|

| Reviews |

4.8

|

4.8

|

4.9

|

4.6

|

4.4

|

4.4

|

| Pricing |

Starts at just $29/month for the first 30 users

|

Starts at $16/user/month

|

Contact vendor for price

|

Starts at $20 per month per user

|

Starts at $45/user/month

|

Starts at $69/month

|

| Free Trial |

yes

14-day

|

yes

|

yes

30-day

|

yes

7 days

|

no

|

yes

|

| Free Plan |

yes

Free Up to 10 users

|

yes

|

yes

No

|

no

|

no

|

no

|

| Use cases |

Best all-in-one maintenance management software solution

|

Good for digital work orders and inspections

|

Good for automation and asset tracking

|

Good for AI insights and inventory tracking

|

Good for predictive maintenance and integrations

|

Good for enterprise operations and compliance

|

| Available on |

Web, iOS, Android, Windows, Mac

|

Web, iOS, Android, Windows, Mac

|

Web, iOS, Android, Windows, Mac

|

Web, iOS, Android

|

What is Maintenance Management Software?

Maintenance management software helps teams plan, track, and stay on top of all their maintenance work. It puts everything into one system, including work orders, asset details, inventory, and schedules, so you’re not relying on spreadsheets or paperwork. With the right tool, you can cut down on downtime, keep equipment running longer, and make smarter decisions about when and how to maintain it.

How Does Maintenance Management Software Work?

Maintenance management software acts as a way to organize all your maintenance work. It lets you create and assign work orders, schedule recurring tasks, track inventory, and monitor equipment performance.

When something needs attention, a work order is created either manually or automatically. It’s sent straight to the technician’s mobile device with everything they need: asset details, location, repair steps, and any required parts. As the job gets done, the tech logs time, notes, and parts used.

All that info is saved automatically, building a full maintenance history for each asset. That makes it easier to spot patterns, plan ahead, and prevent bigger problems down the line.

What Are The Benefits of a Computerized Maintenance Management System?

There are many benefits of adopting maintenance management software to help run your business. These include:

Reduced downtime

By sticking to preventive maintenance schedules and tracking equipment health, maintenance software helps spot issues before they lead to failures. That means less surprise downtime and fewer production delays, keeping things running when they need to.

Improved efficiency

Digital work orders and mobile access can make a big difference to your business. Technicians can pull up everything they need, including task details, asset histories, and manuals, right from their phones. No paperwork, no wasted time, just faster, more focused work.

Extended asset lifespan

With regular maintenance driven by software reminders, equipment stays in better shape for longer. This kind of consistency lengthens asset life, delays replacements, and helps stretch your investment further.

Regulatory compliance

Automated records keep track of all maintenance activity, making audits and inspections much less stressful. For industries with tight regulations, this kind of built-in documentation is a lifesaver.

Data-driven decision making

Built-in reporting and analytics give you real visibility into what’s working and what’s not. You can identify problem areas, adjust your schedules, and make smarter choices when it comes to repairs or replacements.

How Much Does Maintenance Management Software Cost?

Pricing for maintenance management software can vary a lot depending on the features you need and how many people are using it. Most platforms offer tiered plans to suit different team sizes and budgets.

Basic plans usually run between $20–45 per user per month. Mid-tier plans range from $50–85 and add features like inventory management, reporting tools, and mobile access. Enterprise-level systems with advanced analytics and integrations often require custom quotes.

Some tools, like Connecteam, use fixed pricing for up to 30 users, which can be more affordable for smaller teams. Connecteam also has a Small Business Plan, which is completely free for up to 10 users and includes core maintenance features, without the usual restrictions you see in most free versions.

FAQs

The four types are corrective (fixing issues), adaptive (adjusting to new environments), perfective (improving performance), and preventive (avoiding future issues).

CMMS stands for Computerized Maintenance Management System, used to plan and track maintenance. BMS, or Building Management System, controls building operations like HVAC, lighting, and security.

Connecteam is one of the best CMMS options for mobile-first teams. It’s easy to use, affordable, and covers scheduling, work orders, and team communication in one app.

Maintenance management tools help plan, track, and manage equipment upkeep. They include work order systems, asset tracking, preventive maintenance schedulers, and inventory controls.

The Bottom Line On Maintenance Management Software

Choosing the right maintenance management software can shift your team from constantly reacting to issues to staying ahead of them. With the right tool, you can reduce downtime, extend the life of your equipment, and run day-to-day operations more efficiently.

No matter your size or setup, the right software makes it easier to manage tasks, track performance, and make smarter decisions. In the long run, that means more reliable equipment, fewer headaches, and a maintenance team that runs like a well-oiled machine.

If you’re looking for an all-in-one solution that also covers team communication and HR tasks, Connecteam stands out. With its fixed pricing model and free plan for small teams, it’s built to simplify maintenance while keeping your entire team connected.