Use our HACCP audit checklist template as a starting point to customize yours to fit your business.

HACCP Audit Checklist

Make work flow with Connecteam’s digital forms & checklists

- Easily create digital forms and checklists for any task your team needs to complete on the job

- Boost accountability by having employees add a signature, image, or location stamp

- Save time by choosing from a variety of ready-made templates

- Instantly receive your team’s submissions and share reports within your organization

- Use AI to convert PDFs, Excel files, or images into digital forms in seconds—no manual work needed

HACCP Audit Checklist

A well-implemented HACCP plan is crucial for ensuring food safety and compliance with regulations.

This HACCP Audit Checklist provides a comprehensive framework for assessing your food safety management system against the seven HACCP principles.

Utilize this tool to identify strengths, weaknesses, and areas for improvement, ultimately strengthening your commitment to delivering safe and quality food products.

Instructions:

- Conduct this audit regularly, based on the risk level of your operation and regulatory requirements.

- Tailor the checklist to your specific processes and products.

- Assign relevant personnel to different sections of the audit based on their expertise.

- Document your findings and corrective actions clearly.

HACCP Audit Checklist

1. Conduct a Hazard Analysis:

| Statement | Yes/No | Notes |

| Is a written hazard analysis conducted and updated regularly? | ||

| Does the analysis identify all potential biological, chemical, and physical hazards in the process? | ||

| Are the consequences and likelihood of occurrence for each hazard evaluated? |

2. Determine Critical Control Points (CCPs):

| Statement | Yes/No | Notes |

| Are CCPs identified for each identified hazard where prevention or control is essential to prevent or eliminate food safety hazards or reduce them to an acceptable level? | ||

| Are the CCPs justified based on the hazard analysis and scientific rationale? |

3. Establish Critical Limits for Each CCP:

| Statement | Yes/No | Notes |

| Are critical limits clearly defined for each CCP to prevent or eliminate food safety hazards or reduce them to an acceptable level? | ||

| Are the critical limits based on scientific principles and regulations? | ||

| Are monitoring procedures defined to ensure CCPs are under control? |

4. Monitor CCPs:

| Statement | Yes/No | Notes |

| Are CCPs monitored at the frequency specified in the HACCP plan to ensure critical limits are met? | ||

| Are monitoring records maintained and reviewed regularly? | ||

| Are corrective actions taken promptly when critical limits are not met? |

5. Establish Corrective Actions:

| Statement | Yes/No | Notes |

| Are corrective actions pre-defined for each CCP in case critical limits are not met? | ||

| Are corrective actions effective in preventing or eliminating the food safety hazard or reducing it to an acceptable level? | ||

| Are corrective actions documented and reviewed for effectiveness? |

6. Verify HACCP System:

| Statement | Yes/No | Notes |

| Are verification procedures conducted regularly to confirm the effectiveness of the HACCP plan? | ||

| Do verification procedures include on-site observations, record reviews, and validation studies? | ||

| Are verification results documented and used to update the HACCP plan as needed? |

7. Establish Documentation and Recordkeeping:

| Statement | Yes/No | Notes |

| Is the HACCP plan documented and readily available to all relevant personnel? | ||

| Do records of monitoring, corrective actions, and verification activities demonstrate effective implementation of the HACCP plan? | ||

| Are records maintained for the required period according to regulations? |

Additional Observations:

- Overall effectiveness of the HACCP plan and its implementation.

- Training and competence of personnel involved in HACCP activities.

- Management commitment to food safety and HACCP principles.

Recommendations for Improvement:

- Based on your audit findings, identify areas for improvement in your HACCP plan and implementation.

- Develop an action plan to address identified weaknesses and implement necessary changes.

- Monitor progress and continue to refine your HACCP system for ongoing food safety excellence.

Remember: This checklist is a guide and may need to be adapted to your specific operation and regulatory requirements. Always consult with a qualified food safety professional for assistance with HACCP implementation and audits.

By utilizing this HACCP Audit Checklist with Yes/No options, you can simplify the auditing process and make it easier to identify areas for improvement.

Remember, consistent assessment and refinement are key to maintaining a robust and effective HACCP system.

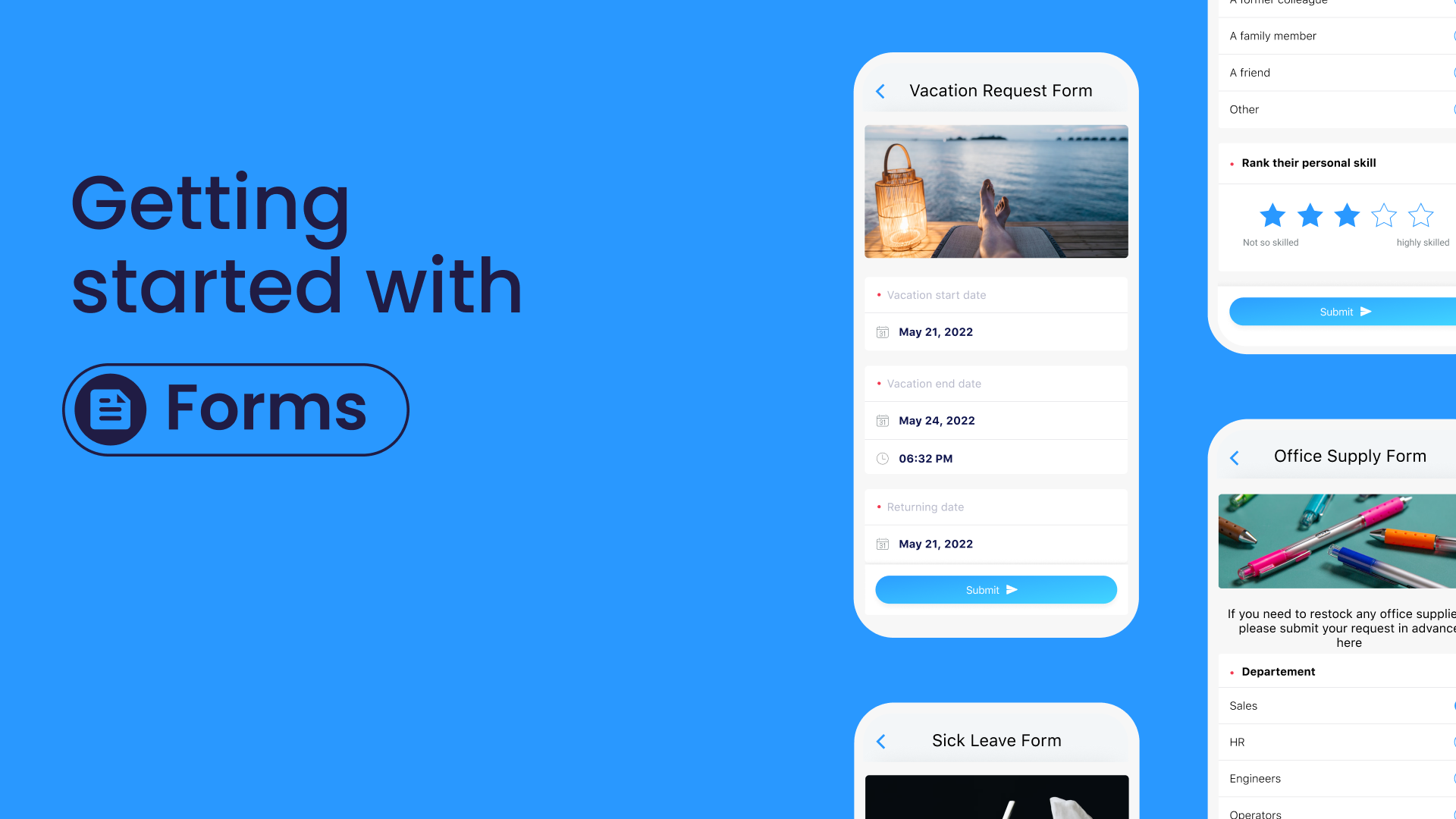

Choose Connecteam, the #1 Choice for Healthy & Safety Managers

Streamline your business’s daily operations and unleash unparalleled efficiency with Connecteam!

Take charge with our Forms and Checklists feature, effortlessly running your daily tasks and delivering the highest standards. But that’s just the beginning!

Easily create perfect employee schedules with our Employee Scheduler, enabling seamless staff organization and maximizing productivity. Keep a tight grip on employee work times using our Time Clock feature, making precise payroll a breeze and freeing you from mundane administrative tasks.

Stay ahead of the game with Connecteam’s built-in employee Chat, fostering real-time collaboration and empowering your team to deliver extraordinary results.

And don’t forget, continuous growth and skill development are at your fingertips with Connecteam’s comprehensive Training & Onboarding features.

Get started with Connecteam for free today and unlock the true potential of your business!

Watch the video below to see it in action:

Ready to boost your efficiency with our pre-made templates?