Calculate your HVAC duct size in just a few easy steps. Use this free HVAC duct calculator to measure the area, velocity, equivalent length, and total pressure drop of your duct system.

HVAC Duct Calculator

We’re glad you’re using our free tool! This resource is web-based and separate from the Connecteam app. Connecteam is an all-in-one solution for managing your team while this free tool is just a little bonus from us to you 🙂

How to Use Our Free HVAC Duct Calculator

Step 1: Enter Your Duct Parameters

- Airflow (CFM): Required. The airflow rate in cubic feet per minute.

- Duct Shape: Choose if the duct is round or rectangular.

- Duct Dimensions: Enter the diameter for round ducts or the width and height for rectangular ones in inches.

- Friction Rate: Inches of water gauge per 100 feet of duct.

- Duct Length: The total length of the duct in feet.

- Number of Elbows: Total number of elbows in your duct system.

- Elbow Type: Select 90-degree, 45-degree, or long radius elbows.

Step 2: Calculate Your Results

Just click the “Calculate” button, and the HVAC Duct Calculator will calculate your results.

Step 3: Review Your Results

After clicking “Calculate,” you’ll see these results:

- Area (sq. in.): This is the cross-sectional area of the duct.

- Velocity (FPM): The calculated velocity of airflow inside the duct.

- Diameter: The diameter or dimensions of your duct in inches.

- Equivalent Length (ft.): This is the total length of the duct, considering the amount and type of elbows.

- Total Pressure Drop (in. w.g.): The loss of air pressure throughout the duct system.

HVAC Duct Calculator

Input Values

Results

What are HVAC Ducts?

HVAC ducts are a core part of any heating, ventilation, and air conditioning system that distribute heated or cooled air throughout a building. They’re usually made from sheet metal, fiberglass, or plastic and are essential for maintaining indoor comfort and air quality.

Measure Your HVAC Ducts Right the First Time

If you’re measuring ductwork for an HVAC system, then you probably already know how important it is to size correctly. Incorrect sizing could lead to poor airflow, high energy costs, and an overworked system. It might seem obvious, but getting your duct size right makes your life (and your client’s life) easier down the line.

Accurate duct sizing isn’t just about complying with building codes; it directly impacts the customer. For example, if the duct is too small, the HVAC system will work overtime to push air through, which can create high static pressure and irritating whistling noises. If it’s too big, the airflow can stagnate and lead to uneven temperature distribution throughout the building.

With the right calculations, a well-designed HVAC system can deliver just the right amount of air where and when it’s needed, minimize energy waste, and keep customers comfortable without straining the system.

How to Calculate HVAC Ducts

Want to know how the math works? Here’s a quick breakdown of the formulas behind our calculator:

First, let’s calculate the duct area. Finding the area depends on the shape of the duct.

For round ducts: π × (Diameter ÷ 2)² = Area

For rectangular ducts: Width × Height = Area

Next, let’s look at how to find the airflow velocity. Using the area we just calculated, you also need to know either the airflow (CFM) or the velocity (FPM) for this formula.

If you have the airflow (CFM): (Airflow × 144) ÷ Duct Area = Velocity

If you have the velocity (FPM): (Velocity × Duct Area) ÷ 144 = Airflow

For the equivalent length for fittings, we use these values for the elbow factor*:

- 90-degree elbow = 5 feet

- 45-degree elbow = 2.5 feet

- Long-radius elbow = 1.8 feet

Here’s the full formula:

Total Equivalent Length = Duct Length + (Number of Elbows × Elbow Factor)

Now that you have the Total Equivalent Length (TEL), you can calculate the Total Pressure Drop**:

Total Pressure Drop = (Friction Rate ÷ 100) × Total Equivalent Length

*The equivalent length values used for elbows and fittings in this calculator and formula are based on our sample estimates. Actual resistance may vary depending on elbow radius, duct material, and installation quality. For precise calculations, refer to manufacturer data or ASHRAE guidelines.

**This calculator provides an estimated total pressure drop based on approximate friction rates and simplified assumptions. Actual pressure loss can be affected by duct material, turbulence, leakage, and additional system components. For detailed system design, consult an HVAC engineer for an advanced duct analysis.

Manage Your Business with Connecteam

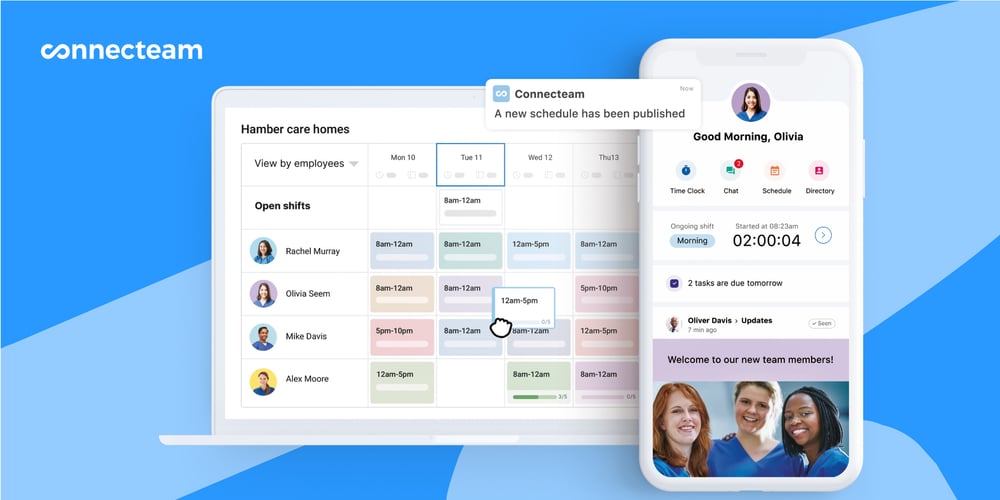

Measuring ducts is just one part of running an HVAC business. Between juggling schedules, managing teams in the field, and keeping customers happy, there’s a lot to stay on top of. Connecteam’s all-in-one HVAC business app makes it easy to manage your entire operation from your phone.

Whether you’re dispatching urgent service calls or tracking job progress in real time, Connecteam gives you the tools to run a more efficient, organized, and profitable HVAC business.

Schedule & Dispatch Jobs in Seconds

Create and share clear job schedules using Connecteam’s Job Scheduling feature, so your HVAC techs always know where they need to be and what needs to get done. Assign jobs based on availability, skills, or location, and attach all the necessary details—like customer information, service tickets, safety checklists, and equipment notes—directly to each shift. Need to make changes? Use the drag-and-drop editor and send instant push notifications so no one misses an update.

GPS Time Tracking for Your Mobile Workforce

Track work hours and locations accurately with Connecteam’s GPS Time Clock. Your techs clock in and out straight from their phones, and you’ll get real-time visibility on their whereabouts during work hours. This makes it easy to eliminate buddy punching, prevent time theft, and simplify payroll with auto-generated timesheets.

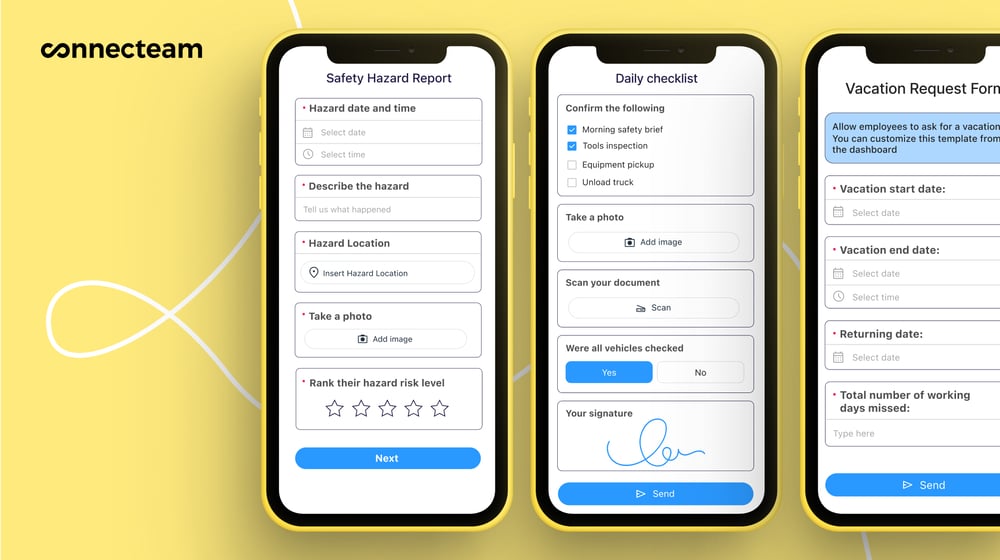

Digital Forms, Checklists & Reports—No Paper Needed

Ditch the paperwork and streamline field reporting with Connecteam’s Forms and Checklists feature. Create digital forms for HVAC inspections, job reports, equipment maintenance logs, and more. You can require mandatory fields, signatures, and photo uploads to ensure every job is completed by the book—and nothing gets missed.

Streamline Communication with Your Team

Keep your entire team connected with Connecteam’s Chat and Updates features. Send 1:1 messages or group chats to coordinate tasks, share safety protocols, or answer questions on the fly. Broadcast company-wide announcements, job updates, or last-minute changes using Updates, ensuring your crew is always informed, no matter where they are.

Task Management Made Simple

Organize and manage your team’s workload with Connecteam’s Task Management feature. Assign tasks to individual technicians or entire teams, set due dates, and track progress in real time. Whether it’s a last-minute repair or a complex installation project, you’ll always have a clear view of who’s doing what—and when it’s getting done.

FAQs

You can input the airflow (CFM) values into the calculator, and it will automatically calculate the area and velocity of your duct. The tool also lets you calculate the equivalent length and pressure drop based on your inputted friction rate and duct dimensions.

Yes! The calculator allows you to choose between round or rectangular ducts. Once you select the duct shape, it adjusts the input fields accordingly, allowing you to enter the appropriate dimensions (diameter for round ducts and width/height for rectangular ducts).

The friction rate represents the resistance to airflow in your duct system. This value is essential for calculating the pressure drop across the ductwork. It is used in combination with duct length and number of elbows to determine the total pressure drop, ensuring your HVAC system operates efficiently.

Enter the number of elbows and choose the elbow type (90-degree, 45-degree, or long radius) from the dropdown menu. The calculator will factor in the equivalent length of each elbow to give you an accurate total pressure drop for the system.

A common rule of thumb for HVAC duct sizing is to allow 1 CFM (cubic foot per minute) of airflow per square foot of room space. However, when it comes to duct dimensions, many HVAC professionals use the guideline of 1 square inch of duct cross-sectional area for every 1 CFM of airflow.

For example, if you need to deliver 400 CFM of air, the duct should have a cross-sectional area of about 400 square inches. Keep in mind that this is a rough estimate. Accurate duct sizing should always consider factors like friction loss, air velocity (typically between 600–1,000 FPM for main ducts), and static pressure to ensure energy efficiency and proper airflow.

For best results, it’s recommended to use an HVAC duct calculator or follow guidelines from ASHRAE or SMACNA.

The “2-foot rule” in HVAC duct design typically refers to keeping the first 2 feet of ductwork from the air handler or plenum as straight and unobstructed as possible. This straight section allows the airflow to stabilize and reduces turbulence before the air makes any turns or goes through fittings.

Following this rule helps:

- Improve airflow efficiency

- Reduce static pressure issues

- Minimize noise and vibration in the system

In simple terms: give the air some room to settle down before forcing it through bends, branches, or transitions. While it’s a general best practice rather than a strict code requirement, many HVAC pros use the 2-foot rule to maintain better system performance and airflow balance.

CFM (cubic feet per minute) isn’t exactly “lost” per foot of ductwork. Instead, air pressure drops as air moves through the ducts due to friction and resistance, which can reduce airflow if not properly accounted for. The actual loss depends on factors like duct size, shape, material, airflow velocity, and the friction rate (measured in inches of water gauge per 100 feet).

As a general rule of thumb:

- Properly sized, straight metal ducts typically have a friction loss of about 0.1 inches of water column (in. w.g.) per 100 feet.

If the duct is undersized, has multiple bends, or uses flexible ducting, friction loss increases, and airflow (CFM) can decrease more noticeably.

To prevent significant CFM loss:

- Keep duct runs as short and straight as possible.

- Use smooth, rigid ducts instead of flex ducts.

- Avoid sharp bends and unnecessary fittings.

For precise calculations of pressure drop and its effect on airflow (CFM), HVAC professionals use friction rate calculations or tools like our HVAC Duct Calculator.